Are merchant couplings the same as wrought steel couplings?

Are merchant couplings the same as wrought steel couplings?

The answer to this is, no!

The answer to this is, no!

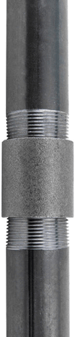

Merchant couplings are produced from a heavy wall steel tube. Sometimes these couplings are inaccurately referred to as wrought iron couplings. Merchant couplings are machined from merchant steel as per the material requirement in the ASTM A865 standard.

Merchant couplings are available in both zinc plated and black options. Standard black couplings up to 2" are dipped in rust preventative and typically larger sizes are phosphate coated.

Merchant couplings are available in both zinc plated and black options. Standard black couplings up to 2" are dipped in rust preventative and typically larger sizes are phosphate coated.

NOTE: The female threads are NPS straight tapped up to and including the 2" size. The 2-1/2” and larger couplings are taper tapped. Half couplings are chamfered at one end only. Deep chamfers allow for easy assembly.

Additional Information & Resources:

Often it is assumed that cast iron and wrought iron are interchangeable terms, however there is a significant difference. The fundamental distinction between cast iron and wrought iron is in how they are produced. The differences can be found in the names; wrought is a past participle of work ("worked iron”), meaning it is shaped, bent, fashioned, twisted, or formed, while cast describes anything formed by the casting process.

Wrought iron is iron that has been heated and then worked with tools.

Cast iron is iron that has been melted, poured into a mold, and allowed to solidify.

Malleable cast iron has been abbreviated to malleable iron (MI). Malleable iron is poured into white iron castings and then subjected to malleable annealing. The malleable annealing decomposes the cementite into flocculent graphite to obtain malleable iron castings.