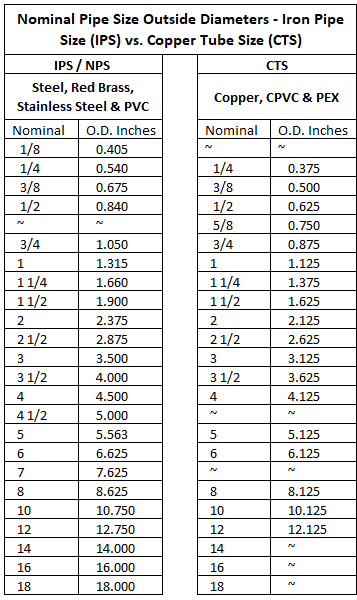

What the difference between Iron Pipe Size / Nominal Pipe Size vs. Copper Tube Size?

Iron Pipe Size (IPS) was the first pipe size system used in plumbing systems. With the introduction of copper piping, Copper Tube Sizes (CTS) came on the scene, followed by CPVC and PEX.

It is important to know what pipe sizing system you are working with when ordering fittings and valves. Fittings designed for IPS will not work on CTS piping or tubing and vice versa.

Iron Pipe Size (IPS) - Carbon Steel, Red Brass, 304 / 316 Stainless Steel, & PVC. IPS is prevalent in general piping and industrial applications.

Copper Tube Sizes (CTS) - Copper, CPVC, & PEX. CTS is specific to plumbing and potable water systems.

The main difference between IPS and CTS is the actual outside diameter.

IPS used to be a standard for welded wrought iron pipe only. This was controlled by the inside diameter. When Nominal Pipe Size (NPS) essentially took over for IPS, it also became an O.D. controlled value based on ASME B36.10., and thus the diameter differs from the nominal diameter. Industry still uses the IPS terminology rather than NPS to avoid potential confusion with National Pipe Straight, which is part of the ASME B1.20.

For both CTS and IPS, there is another measurement that refers to the wall thickness of the pipe or tubing. In CTS, tube dimensions are specified by an exact O.D. and a tube wall thickness. Due to advances in manufacturing technology, several wall thicknesses are now available, in the past only ⅛” wall thickness was available. In IPS, pipe dimensions are defined by a Nominal O.D. (which is different from the measured or actual O.D) and a “Schedule” that relates to pipe wall thickness.

Since CTS is O.D. controlled, a change in wall thickness will change the inside diameter and will change the flow rate inside the pipe. In copper, the wall thickness of the tube is designated by the letters K, L & M. Type K is the thickest, Type L is intermediate, and Type M has the thinnest wall. For other types of pipes such as CPVC and PEX (Types A, B & C), wall thickness is designated by the standard dimension ratio (SDR), which is defined as the ratio of the outside diameter to wall thickness and has a typical value in the range of 7.4 to 13.5.

With IPS, there is a wide range of wall thickness options. The wall thickness is specified by schedules. Schedule 40 and 80 pipes are the most used in plumbing applications, however the list of schedules ranges from 5 (thin wall) to 160 (heavy wall).

It is important to note that that as the schedule number increases, the wall thickness increases, enhancing the ability of the pipe to handle greater pressures. However, this results in a decrease in the pipe I.D. (inside diameter) and a reduction of the flow inside the pipe. Regardless of the wall thickness, both the nominal and measured O.D. do not change.