What size of float ball do I need?

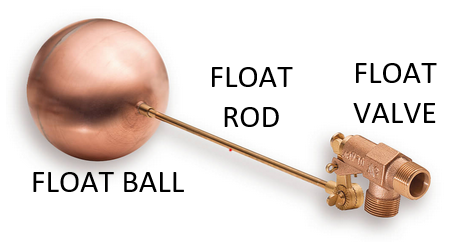

The Float Valve - Rod and Float Ball Sizing Guide below is to be used as a guide only to assist you in selecting appropriately sized float valve components.

There may be unforeseen factors such as turbulence or pressure surges in your system which may affect the float valves performance. There may be instances where you need to either increase the length of the rod for increased mechanical leverage or increase the float ball diameter for additional buoyancy. The longer the rod and larger the float ball, the greater the closing pressure of the plunger against the float valve seat.