What is the purpose of a BOB07NL 3/4" Brass Bleeder Orfice?

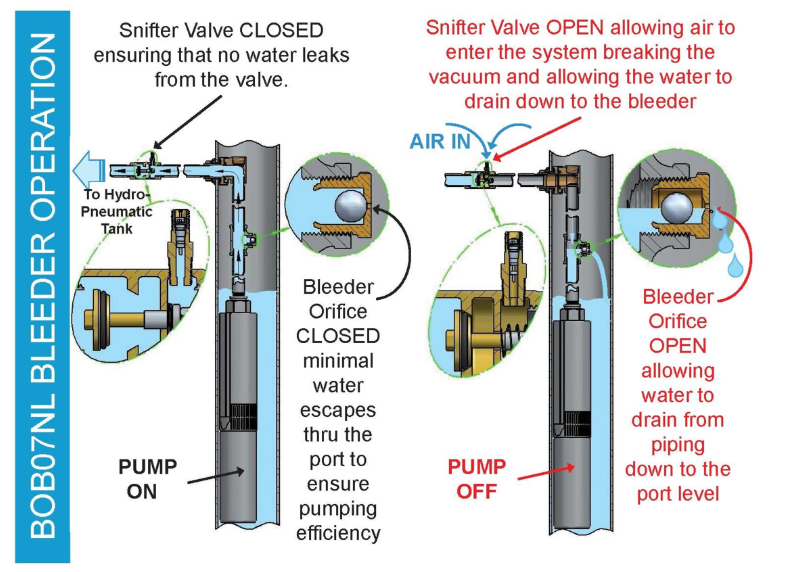

Bleeder valves are used to add air into a galvanized or glass lined pressure tank, which is not a "PRE-CHARGED" tank design.

Bleeder valves are used to add air into a galvanized or glass lined pressure tank, which is not a "PRE-CHARGED" tank design.

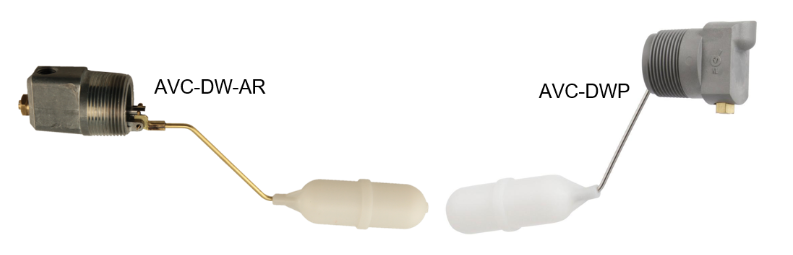

The air that is in the drop pipe after the bleed is forced into the tank at the start of each pump cycle to precent the tank from becoming waterlogged. Any excess air is released from the tank using a "Deep Well Air Release Valve" Part No AVC-DWP or AVC-DW-AR which is installed in the pressure tank, this maintains a consistent air to water ratio in the tank at all times.

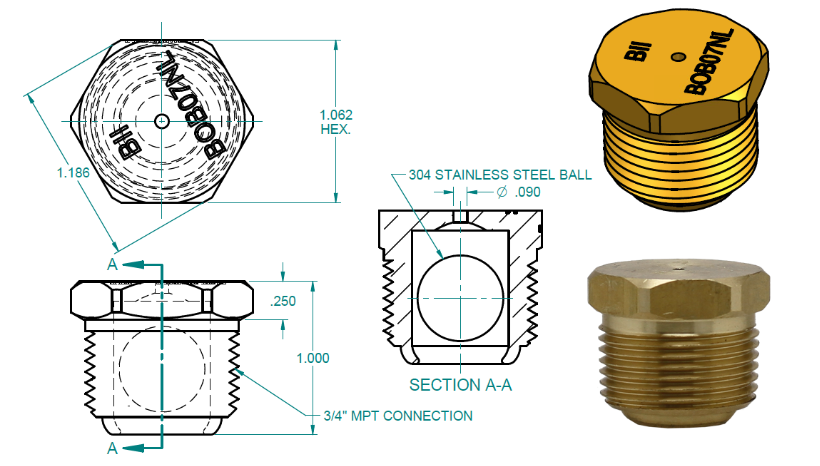

The BOB07NL 3/4" Brass Bleeder Orifice device is installed into the drop pipe in a well which is intended to drain the pipe down to a certain level while letting air take it's place. It is installed below frost line, above the static head . It is threaded into a tee fitting in the drop pipe of a submersible pump installation, typically 10 to 12 feet below the well head. or about ten feet from ground surface in most installations. The 0.090" bleeder orifice provides a quick water bleed through its orifice (opening) when pump shuts of, air is drawn in through a snifter valve to break the vacuum and allow the water to drain down to the level of the bleeder port.

When the pump starts the air above the bleeder orifice is forced into the pressure tank, the orifice remains completely closed while the pump is running preventing leaking, which would result in the loss of pumping volume.

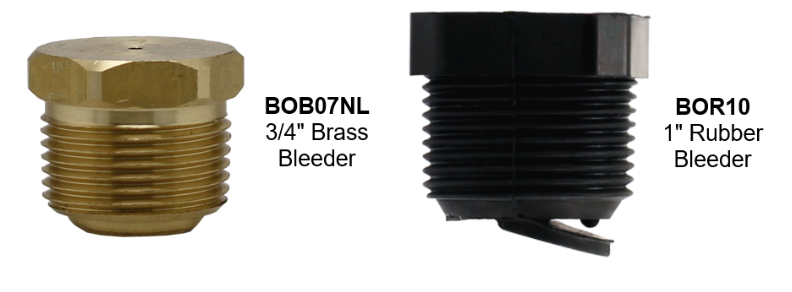

Both the BOB-07NL ¾” Brass & the BOR10 1” Rubber Bleeders (Drain Back Valves) work on the same Principle.