What is the difference between 304 and 316 grade stainless steels and what are their typical applications?

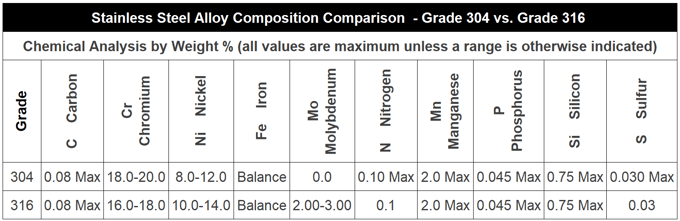

When it comes to 304 vs. 316 stainless steel both are good for corrosion resistance, however due to differences in the alloy composition, 316 stainless gets the slight edge in all categories including corrosion resistance, strength, welding, and heat resistance. With regards to the chemical composition of the alloys, the main difference between the two is the addition of molybdenum in grade 316. While grade 304 may have trace quantities of molybdenum, this element exists in a higher percentage (2% to 3%) in 316. When Molybdenum is added it significantly improves the corrosion resistance properties of an austenitic stainless steel alloy.

Type 304

Type 304 Stainless Steel is the most widely used of the austenitic (chromium/nickel) stainless steels. In the annealed condition it is essentially non-magnetic and becomes slightly magnetic with the application of cold work. Type 304L stainless steel is preferred in welding applications to exclude the formation of chromium carbides during cooling in the heat affected region of the weld. These alloys represent an excellent combination of corrosion resistance and fabricability.

Type 304 Applications:

- Chemical and Petrochemical - Processing

- pressure vessels, tanks, heat exchangers, piping systems, flanges, fittings, valves and pumps

- Medical

- Mining

- Petroleum Refining

- Pharmaceutical Processing

- Power Generation — nuclear

- Pulp and Paper

- dye tanks, pipelines buckets, dippers, etc. that come into contact with the formic, acetic, and other organic acids used in the dyeing industry

- Food and Beverage Processing

- Ability to withstand the corrosive action of various acids found in fruits, meats, milk, and vegetables.

- The citrus and fruit juice industry also uses Type 304 for all their handling, crushing, preparation, storage and hauling equipment.

- Type 304 is used for sinks, tabletops, coffee urns, stoves, refrigerators, milk and cream dispensers, and steam tables.

- Used in numerous other utensils such as cooking appliances, pots, pans, and flatware.

- Dairy equipment

- milking machines, containers, homogenizers, sterilizers, and storage and hauling tanks, including piping, valves, milk trucks and railroad cars.

- mills, bakeries, and slaughter and packing houses, all metal equipment exposed to animal and vegetable oils, fats, and acids is manufactured from Type 304.

- Brewing equipment - used in pipelines, yeast pans, fermentation vats, storage, and railway cars, etc.

Type 316

Type 316 stainless steel is ideal for severe environments. Of course, there are many industrial processes that require a higher level of resistance to corrosion than Type 304 can offer. For these applications, Type 316 is the answer. 316 is an austenitic chromium nickel stainless steel containing molybdenum. The addition of molybdenum increases general corrosion resistance, improves resistance to pitting from chloride ion solutions, and provides increased strength at elevated temperatures. As such, molybdenum is one of the single most useful alloying additives in the fight against corrosion, particularly against sulfuric, hydrochloric, acetic, formic, and tartaric acids, acid sulfates and alkaline chlorides. This alloy is also somewhat stronger at elevated temperatures compared to Type 304.

Type 316 Applications:

- Chemical and Petrochemical Processing

- pressure vessels, tanks, heat exchangers, piping systems, flanges, fittings, valves, and pumps

- Industrial Equipment

- handles the corrosive process chemicals used to produce inks, rayons, photographic chemicals, paper, textiles, bleaches, and rubber.

- Food and Beverage Processing

- Marine

- Type 316 is the main stainless used in the marine environment, except for fasteners and other items where strength and wear resistance are needed, then Type 304 (18-8) is typically used.

- Medical Equipment

- Type 316 is also used extensively for surgical implants within the hostile environment of the body.

- Petroleum Refining

- Pharmaceutical Processing

- Power Generation — nuclear

- Textiles

- Water Treatment

- Exhaust manifolds,

- Furnace parts, heat exchangers, pharmaceutical and photographic equipment

- Pulp and Paper

- Type 316 can withstand corrosive attack by sodium and calcium brines, hypochlorite solutions, phosphoric acid; and the sulfite liquors and sulfurous acids used in the paper pulp industry.