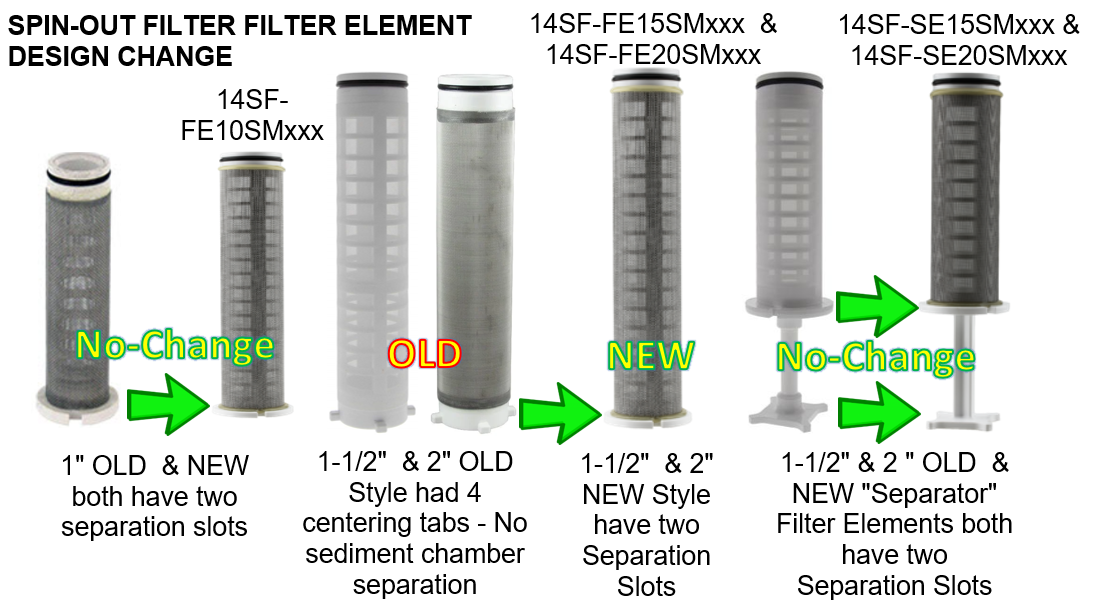

Spin-Out Filter Element Update: A Change to 2 Slot Disc vs. 4 Tab Design

Spin-Out Filter Element Update: A Change to 2 Slot Disc vs. 4 Tab Design

The long 1-1/2” & 2” filter elements which had 4 tabs on the bottom to center the screened filter element in the housing were updated to improve their function. The 4-tab system centered the filter element but did not provide separation between the spinning water that separates out the particulate using centrifugal force in the upper section of the clear polycarbonate filter bowl and the accumulated sediment (sand) in the lower section of the sediment chamber. In the past we had some customer complaints about the 4-tab design sighting that the filtered sand was always agitated and continuously spinning in the chamber.

The new version of the 1-1/2" and 2" filter elements were altered to have a round disk with two openings like the 1” filter element. This ensures the 1-1/2” & 2” separator filter elements (2/3 length screen with lower stem) allow the sand to settle down into the sediment storage chamber through the smaller slots. The disc provides sufficient separation of the upper section which spins the water and separates the sand using centrifugal force, while the separated sand remains undisturbed in the lower chamber eliminating unnecessary wear due to abrasion.

You will notice that the BOSHART separator elements use both systems. A round disc with two slots separates the spin-out section of the filter from the sediment storage section & the 4-tab system is used to center the element at the bottom of the bowl where there are no issues due to agitation.

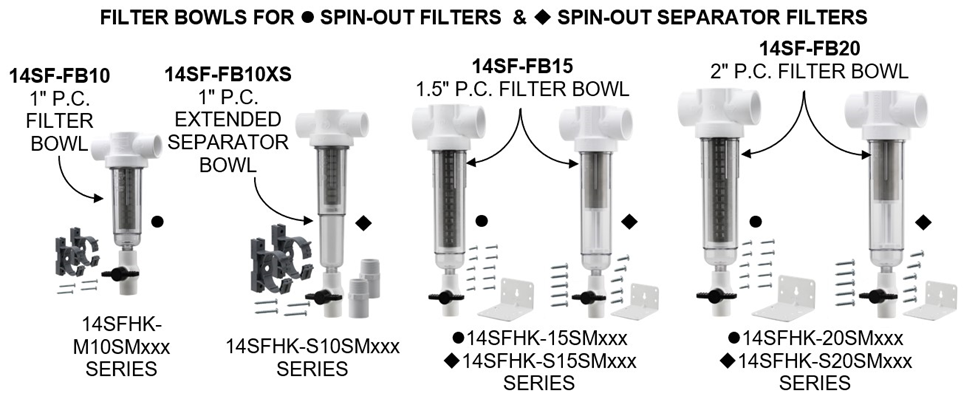

Note that the 14SF-FE15SMxxx & 14SF-FE20SMxxx filter have a smaller sediment separation chamber.

When you get a question on why the replacement filter screens have changed, this article will be helpful in providing the reasoning. The fit and function has not changed.