Should I install a vacuum breaker on my faucet's hose bibb connection?

Should I install a vacuum breaker on my faucet's hose bibb connection?

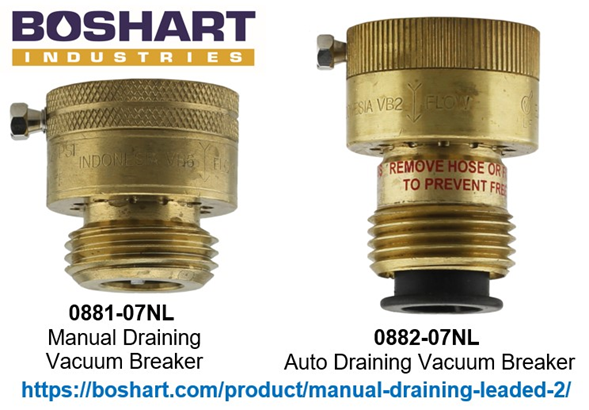

If your faucet has a garden hose connection and does not have a built-in vacuum breaker, then a vacuum breaker should be installed on each faucet or hose bibb that is connected to the potable water supply. This is an integral part of the faucet and will help to prevent backflow into the water supply.

If your faucet has a garden hose connection and does not have a built-in vacuum breaker, then a vacuum breaker should be installed on each faucet or hose bibb that is connected to the potable water supply. This is an integral part of the faucet and will help to prevent backflow into the water supply.

INSTALLATION:

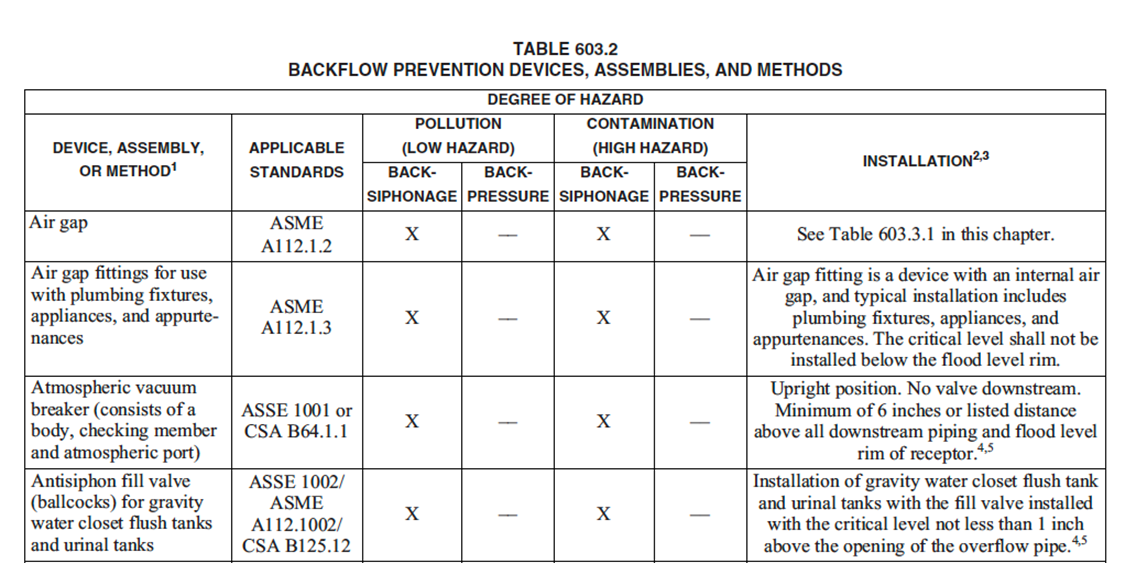

Vacuum breakers must be installed at least six inches above the ground surface and must follow the installation parameters in the 2021 Uniform Plumbing Code Table 603.2.

ALWAYS ADHERE TO ALL APPLICABLE PLUMBING CODES:

Breaking the set screw head off is mandated by plumbing codes in many areas. You must make sure to comply with all applicable plumbing and building codes for your area.

Vacuum breakers are supplied with a “break-away” set screw. The head of the screw will break off when tightening torque is applied. Breaking off the screw head prevents the removal of the vacuum breaker once it is installed. Once the vacuum breaker is installed, no further adjustments are required.

Vacuum breakers are supplied with a “break-away” set screw. The head of the screw will break off when tightening torque is applied. Breaking off the screw head prevents the removal of the vacuum breaker once it is installed. Once the vacuum breaker is installed, no further adjustments are required.

OPERATION:

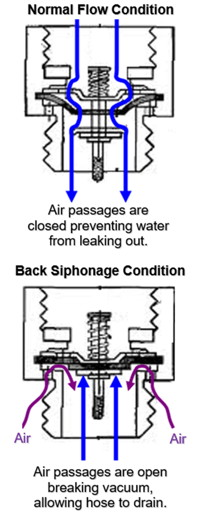

A vacuum breaker prevents back flow to the water supply by venting water and discharging it onto the ground (to the atmosphere). When conditions for back flow exist, a spring-loaded check valve is opened by the back flow and the water will be discharged to the atmosphere.

A vacuum breaker prevents back flow to the water supply by venting water and discharging it onto the ground (to the atmosphere). When conditions for back flow exist, a spring-loaded check valve is opened by the back flow and the water will be discharged to the atmosphere.

When the system pressure is sufficient to open the check valve, flow is directed through the vacuum breaker into the garden hose. When the supply pressure is interrupted or when the pressure in the hose becomes greater than the supply pressure, outflow stops and the spring-loaded check valve closes, simultaneously opening a vent to the atmosphere. In this mode of operation, any water that flows backward through the vacuum breaker is vented onto the ground.

Normal Flow Condition:

Water pressure pushes the rubber sealing disc off its seat allowing water to flow through the openings.

Back Siphonage Condition:

When a vacuum occurs, the spring pulls the valve closed before any reverse flow can take place. The rubber disc seals against the valve seat.

VACUUM BREAKER REPLACEMENT:

The broken set screw results in a significant problem when the hose vacuum breaker needs to be replaced. This requires cutting the vacuum breaker body about ½ way through in two or more areas. Then, the body section with the broken screw must be physically broken off. This allows the breaker to be unthreaded from the faucet bibb.

The broken set screw results in a significant problem when the hose vacuum breaker needs to be replaced. This requires cutting the vacuum breaker body about ½ way through in two or more areas. Then, the body section with the broken screw must be physically broken off. This allows the breaker to be unthreaded from the faucet bibb.

If a break off screw is NOT mandated by code in your area, some installers choose to replace the break-away set screw with a standard #10-32 screw to prevent it from being removed accidentally when the garden hose is removed.

WALL HYDRANT WITH BUIT-IN VACUUM BREAKER:

The best way to avoid the issues with regards to the hose bibb vacuum breaker replacement is to install a wall hydrant that has the vacuum breaker feature built in the body of the faucet rather than being attached to the hose bibb.