Shallow Well Air Volume Controls

Air volume controls (AVCs) can be sorted into two basic types:

#1 – Shallow Well AVCs (a.k.a. Air Chargers)

#2 – Deep Well AVCs (a.k.a. Air Releases)

In this article we are going to look at shallow well AVCs (Air Chargers). If you are looking for information on deep well AVCs (Air Releases) you will find detailed information at the link below:

https://support.boshart.com/deep-well-air-volume-controls-avc-a.k.a.-air-release-valves

Shallow Well Pump Installations

In shallow well installations, a jet pump is at the ground surface and creates a vacuum which draws water from the well. More accurately, the pump allows the atmospheric pressure in the well to push the water to the surface. Typically, shallow well pumps will not pump water from any deeper than approximately 28 ft. Additionally, as the elevation is increased from sea level, the pumping depth will decrease accordingly.

Shallow well AVCs have a tube attached to the suction side of the pump which sucks in air from the atmosphere each time the pump runs. This air is then injected through the piping from the pump into the tank during each pump cycle.

The purpose of the air charger is to open and close a valve as the water level within the tank changes. When the water level is high inside the tank, the valve is opened allowing the pump to draw (suck) air from the room, through the tube, through the open valve in the AVC, and finally into the tank.

When the tank has sufficient air (proper air to water ratio) the control closes the valve, and no more air is injected into the tank until required.

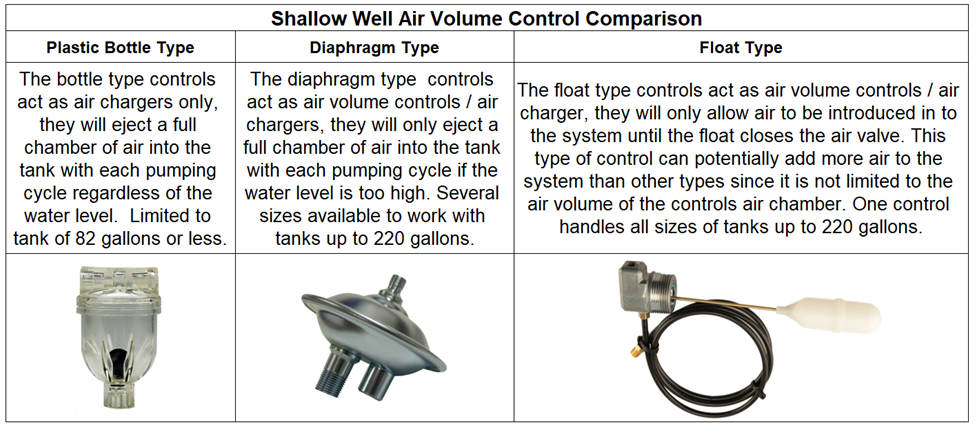

There are 3 basic styles of shallow well AVCs (air chargers) available. ALL TYPES INJECT AIR INTO THE TANK!

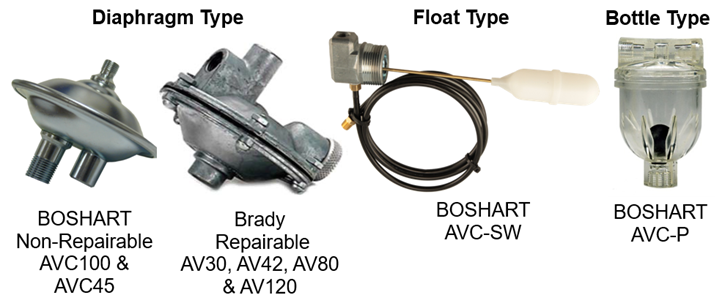

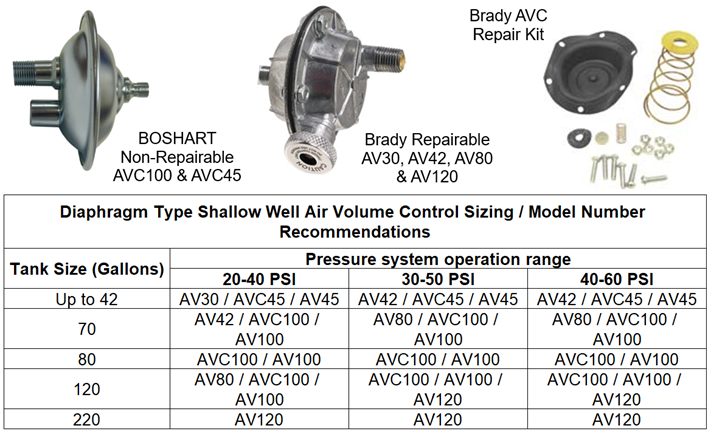

Diaphragm Type Shallow Well AVCs

Diaphragm type shallow well AVC installation:

The AVC is mounted on the tank about 1/2 way up. A 1/4" tubing is connected from the AVC to the suction of the pump.

The drawdown of an atmospheric tank is only 10% when the pressure is set to 30 PSI cut-in and 50 PSI cut-out. EXAMPLE: 8.2 Gallons (10% of 82) can be drawn from an 82-gallon atmospheric tank before the pressure drops from 50 PSI to 30 PSI.

Diaphragm type shallow well AVC operation:

“Water level too high - Tank needs additional air”

#1 - When the pump starts, the diaphragm in the AVC is drawn to the right by pump suction through the tubing attached to the pump housing.

#2 - Air enters through the air inlet valve when the water level in tank is above the connection to the air control. Air enters until the suction has pulled the diaphragm all the way to the right, compressing the spring.

#3 - The spring pressure forces the diaphragm to the left immediately after the pump stops and the pressure equalizes. This forces the air through the check valve in the AVC tank connection into the tank.

#4 - The spring forces the diaphragm all the way to the left discharging all the air into the pressure tank. When all the air is ejected the check valve in the AVC tank connection closes keeping the water from entering the control.

“Water level too low - Tank does not require additional air”

#1 - When the water level is below the connection to the air control (i.e the tank has too much air), the pump starts and the diaphragm in the AVC is drawn to the right by pump suction through the tubing attached to the pump housing.

#2 - Air enters through the control from the tank through the AVC tank connection check valve removing air from the tank. No air is drawn in through the air inlet valve when the water level in tank is below the connection to the air control. The suction pulls the diaphragm all the way to the right compressing the spring fully.

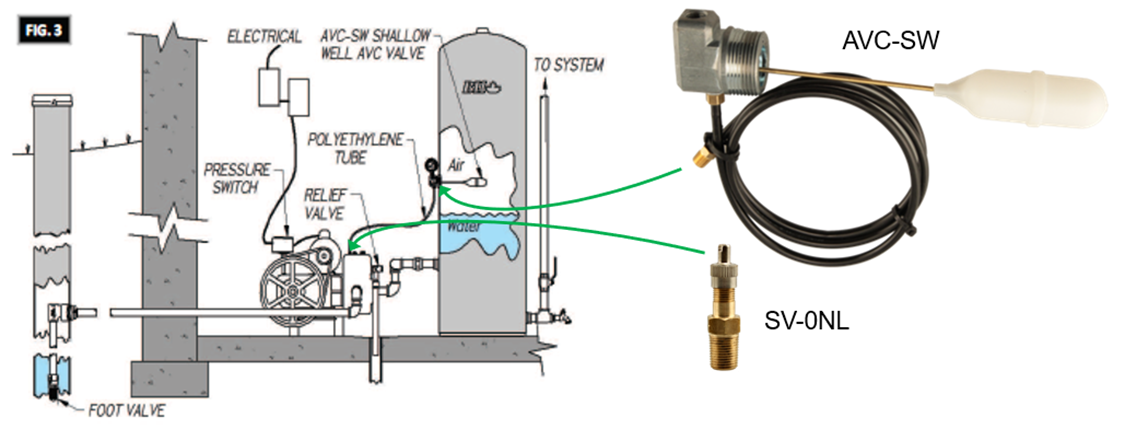

Float Type Shallow Well AVCs (AVC-SW)

AVC-SW Shallow Well Operation:

When the water level is high, the float, secured to a float rod extending through a flexible dividing wall, opens an air inlet valve in the body of the control. The air inlet valve is connected through a 48” long polyethylene tube to a snifter valve on the pump and has no direct connection into the tank. The snifter valve admits air into the pump but prevents the water in the pump from escaping back through it. Air is drawn into the pump through the air inlet valve, through the connecting tubing and snifter valve, and carried out with the water into the tank. This operation continues until the volume of air increases to the proper amount, at which time the float closes the air inlet valve, shutting off the supply of air to the pump. The optimum relationship between the volume of air and water in the tank is thus maintained.

Connecting the airline to the pump housing:

A snifter valve with a light (or possibly no-spring valve core) is installed into the pump housing on the suction side. The snifter valve cap is discarded and replaced by a special fitting that allows a section of tubing to be installed between the pump and the AVC.

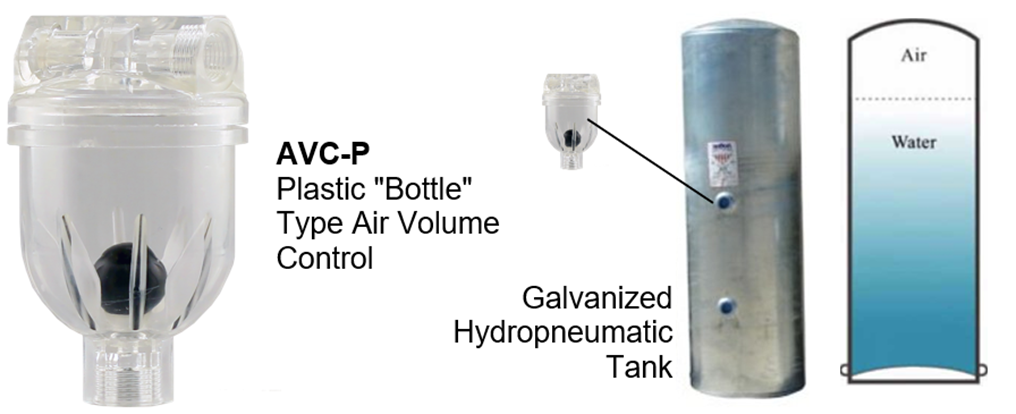

Bottle Type Shallow Well Jet Pump AVCs (AVC-P)

The AVC-P fits all hydro-pneumatic pressure tanks up to 82 gallons. They are specifically designed to prevent waterlogging typically associated with a conventional galvanized pressure tank. The AVC-P automatically maintains a proper balance of air and water volume in the tank. Maintaining the proper air to water ratio eliminates frequent starts and stops, thus extending motor life and reducing power consumption. The AVC-P eliminates issues with water-logged tanks which result in rapid pump cycling, which requires frequent tank draining when tanks are installed without an air charger.

Hydro-pneumatic type tanks use the air within the tank to maintain pressure on the water system. Unlike water, air can be compressed. Compressed air acts like a giant spring which pushes the water from the tank providing water between the pump cycles (drawdown). Over time, the captive air can be absorbed into the water, reducing the internal tank pressure and useable water between pump cycles. This will eventually result in a waterlogged tank. The remedy is to drain the tank, so the air is replaced, or to pump air into the system through an air valve.

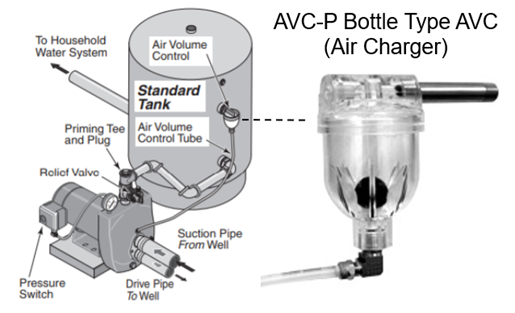

AVC-P Shallow Well Installation:

The bottle type AVC is mounted in the tank accessory port about 1/2 way up. A 1/4" tubing (A) is connected from the AVCs lower ¼ FPT connection to the suction side of the pump.

AVC-P Shallow Well Operation:

AVC-P Shallow Well Operation:

When the pump starts, air is drawn through the check valve (C) and inlet port (D) until the bottle chamber (E) is full of air at which time the floating ball (F) closes against the lower valve seat (G) and no more air is drawn in through the remainder of the pumping cycle.

When the pump stops, the air that is trapped in the bottle chamber (E) bubbles up through the ball check valve (H), through the tank connection of the AVC, and into the tank through the short pipe nipple. The floating ball (F) rises to the top of the air chamber and the air charger is ready for the next pump cycle.