My well (sand) point screen has become clogged, do you have any ideas on how to clean it out?

This is a very difficult question to answer as each case can be different from the next, however there are a couple of things you can try before going to the last resort of pulling it up and replacing it.

There are two common reasons for the screens getting clogged, the first is that it is plugged with sand and the second is that in some areas where iron is present, the buildup of iron causes the screen to become clogged over time.

#1 – SAND / SILT

If the point is driven in very fine sand or silt, the flow of water into the point causes the very fine sediment to settle against the sand point and plugs the screen. If this is the cause you might be able to back wash it. You need to have a supply of water and a means to pump it back down through the sand point. By pumping water back down and out through the screen it is sometimes possible to dislodge the sand or silt and move it away from the screen, allowing water to once again flow through the screen. It is impossible to say how long the point will remain operational before the back wash process may need to be done again.

#2 – IRON BUILD UP

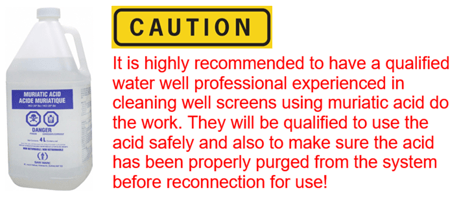

If you think that it is plugged by iron build up, the rust build up can sometimes be removed with muriatic acid. You can buy this at most hardware stores. Pour the muriatic acid down the well point and leave it to work.

CAUTION: Always adhere to good safety practices when using muriatic acid. Muriatic acid may be less concentrated than hydrochloric acid, but it is still capable of causing burns to the skin and eyes. Always wear protective clothing when handling muriatic acid, including long sleeves, pants, gloves, and goggles or glasses. After a few hours start the pump and pump a significant volume of water to clear all the muriatic acid before attaching the well point back to the system.

Unfortunately, we cannot predict the success rate of these solutions, in some cases these methods are successful and other times they are not! However, it just may save you from pulling and replacing the well point.