How to Make a Stainless Steel Pinch Clamp PEX Connection

How to Make a Stainless Steel Pinch Clamp PEX Connection

Using stainless steel pinch clamps, also referred to as ear clamps, are a great way to connect PEX pipe to PEX fittings. Connections made using SS pinch clamps with an interlocking design provide the same high integrity connection as a copper crimp ring connection. Pinch clamps can be used on stainless steel, brass, and poly fittings.

In this blog we will go over the tools required and the step by step process for installing stainless steel pinch clamps. Please review all of the steps in the installation instructions before getting started.

Tools Required

- Pipe Cutter

- Ratchet Type Pinch Clamp Tool

Getting Started

There are four advantage to using pinch clamps. First, it is almost impossible to make a bad joint when using a ratchet action type pinch clamp tool. This tool does not allow itself to return to its original open position until it has been completely closed. This ensures the ear of the clamp has been properly formed, fully compressing the connection. The second is that a single tool is used for all sizes from 3/8” to 1”. Third, the pinch clamp system is easier to use when making connections in tight, hard to access locations. Last but not least, it is easy to determine if the connection has been made by visually inspecting the formation of the ear on the clamp.

The system can be hand fit together, then the installer can go back and pinch each clamp to make the connection permanent. After all connections have been pinched, the system can be pressure tested immediately. Pinch clamps, like copper crimp ring connections, are immediately permanent whether the installation temperature is hot or cold. Unlike Cold Expansion PEX (CEP) connections, there is no need to wait for the pipe to return to a set position.

Step #1

Step #1

Using a pipe cutter, cut the pipe to the desired length making sure the cut is smooth and square to the end of the pipe. A rough, jagged or angled cut may result in a failed connection. DO NOT use a hacksaw.

Step #2

Select the correct sized pinch clamp and slide the clamp approximately 2” past the end the of the PEX pipe.

Step #3

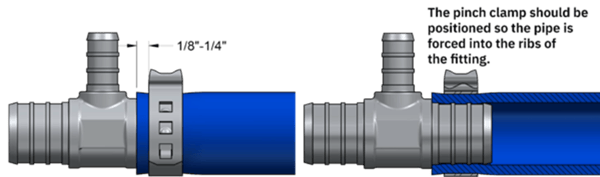

Insert the fitting into the PEX pipe until it touches the shoulder of the fitting. Then slide the pinch clamp back towards the fitting, positioning the clamp 1/8” - 1/4” from the end of the pipe.

This distance is critical to ensure that the crimp ring is positioned directly over the ribs or barbs of the fitting.

Step #4

Step #4

Position the open jaws of the ratchet type pinch clamp tool over the raised ear of the clamp and squeeze, making sure the handles are fully closed to properly compress the connection.

NOTE: The tool is designed so it will not open unless the tool has been fully closed.

Step #5

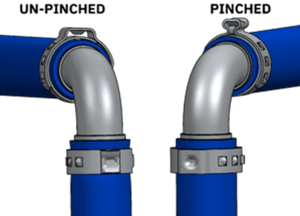

Inspect the clamp and ensure the connection is secure. Proper clamping can be easily verified by visually checking the ear clamp. The ear must be formed as in the illustration which shows a clamp before it is pinched (left) and a properly formed, pinched clamp on the right.

Visually inspecting each connection is a quick and easy way to ensure all connections are properly secured. These instructions apply for both metal and poly PEX fittings. Check out this blog on how to remove the stainless steel pinch clamps. Remember, if the fitting isn't damaged it can be reused!