How do I select a check valve for my sump pump application?

There are 4 key factors to consider when selecting a sump pump check valve.

#1 – Desired Connection Type

There is a wide range of sump pump check valve models available, from economy series to more robust types. The economy BSC Series (Rubber Flapper Type 1-1/4”, 1-1/2” & 2”) ABS sump pump check valves have various connection types including threaded, slip, flexible rubber couplers, and barbs. The more robust flapper types like 17-SPCV white PVC check valves (17SPCV-1215, 17SCC-15, & 17SCC-20) have compression connections. 1-1/2” & 2” sizes are also available with slip connections (17SCS & 17QSCS Series) and true union slip connections (17SCTU & 17QSCTU Series).

#2 – Pressure / Temperature Rating Required

Depending on the required pressure and temperature rating required (see ratings above), these ratings may impact the model of valve you can select. For example, the BSC sump pump check valves are only rated to 25 PSI at 140°F (60°C) whereas the PVC valve are suitable for 150 PSI at 72° F (22°C). NOTE: End blocking of all compression connections is required to prevent linear pipe movement or blow-off.

#3 – Valve Size & Flow Velocity

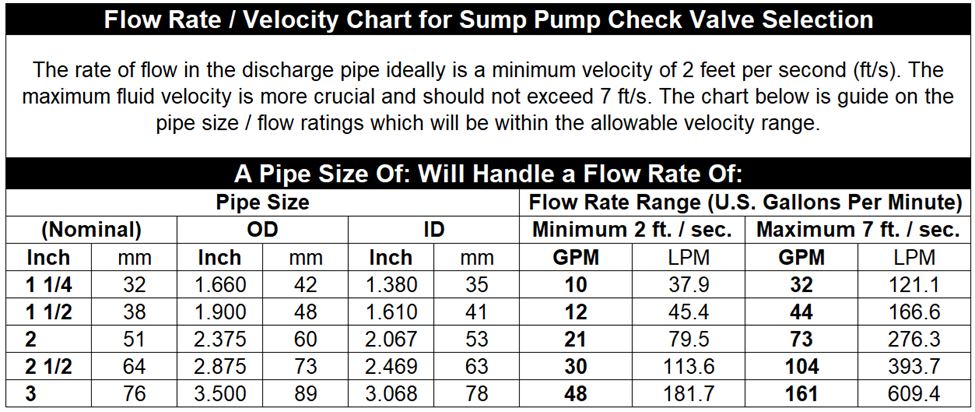

Valve size is also important, and one must refer to the pump manufacturer's installation instructions. Typically, the discharge piping must be equal to or larger than the discharge connection on the pump. A reduction in the discharge piping could potentially void the pumps warranty. The velocity at which the water is discharged through the valve and piping also needs to be taken into consideration. Velocity is often overlooked, but under sizing will result in a flow velocity that is too high. This is a common cause of damage and failure of the piping and valve due to hydraulic shock or water hammer. On the other hand, oversizing can result in a buildup of debris as water traveling too slowly cannot flush dirt from the valve components.

The chart below provides the minimum and maximum gallon per minute (GPM) depending on the piping size in order to maintain a desirable flow rate between 2 feet per second (fps) and 7 fps.

#4 – Gravity vs. Spring Assist (Quiet) Closing Design

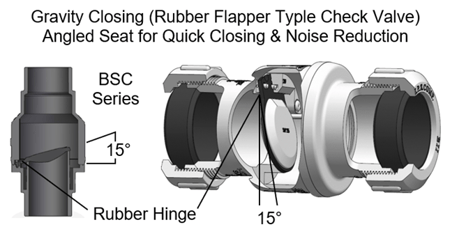

GRAVITY CLOSING TYPE - One should consider that gravity closing type valves tend to be noisy due to the flapper slamming closed each time the flow reverses when the pump stops. The Boshart gravity closing (rubber flapper type) check valves are designed with a 15°degree valve seat which reduces the time and force at which the flapper contacts the valve seat. Therefore, they are less noisy than many sump pump check valves on the market.

Rubber flapper valves in which the gasket seal doubles as the flexible hinge for the flapper are best suited for smaller, low HP pumps with low GPM ratings. For example a pump discharging 21 GPM @ 2 ft/s asserts much less strain on the hinge than a high HP, high capacity sump pump discharging 73 GPM at 7 ft/s velocity in which case the fluid asserts a great deal of force on a rubber flapper. For high capacity pumps the selection of a stainless hinge pin type valve is a better choice.

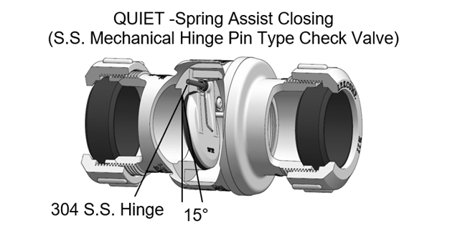

SPRING ASSIST “QUIET” CLOSING TYPE - The Selection of a spring assist “Q” series QUIET Sump Pump check valve is highly recommended. They do cost a little more, however they are worth every penny. A silent swing check valve is manufactured with a S.S. mechanical hinge pin. This hinge system is much more robust and will have a longer life expectancy. The spring closes the flapper as the pump stops, eliminating all flow reversal and water hammer, and therefore their closing is silent. The reduction in wear and tear on the valve and piping will extend the life expectancy of the system. You cannot go wrong selecting a valve with a mechanical hinge system and they will perform well in all applications regardless of whether the pumps horsepower (HP) or capacity (GPM) is low or high.

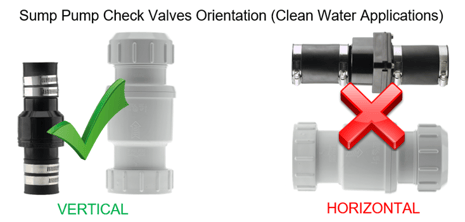

INSTALLATION: Check valves used in clean water applications such as sump pump installation must be installed in the VERTICAL orientation for optimal performance.

IMPORTANT: The installer must always make sure the check valve installation complies with all applicable plumbing and building codes.