How can I install a Pitless Adapter in a large diameter corrugated steel pipe?

Installing a Pitless Adapter in corrugated casing:

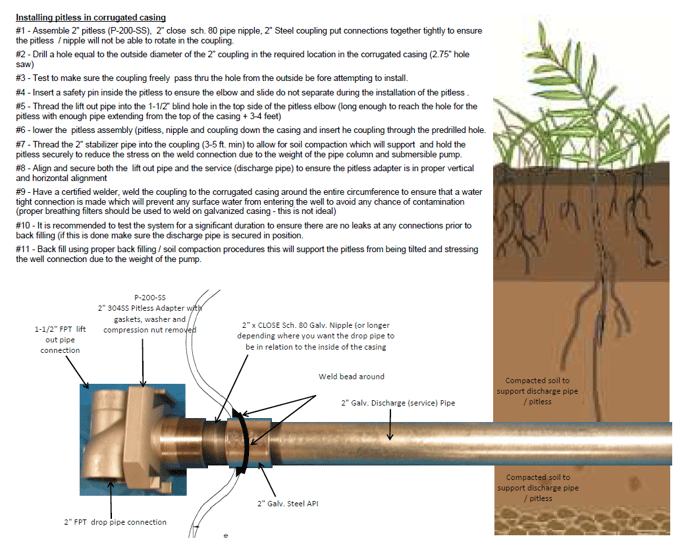

#1 - Assemble a 2" pitless (P-200-SS), 2" close sch. 80 pipe nipple, and 2" steel coupling. Put connections together tightly to ensure the pitless and nipple will not be able to rotate in the coupling.

#2 - Drill a hole equal to the outside diameter of the 2" coupling in the required location in the corrugated casing (2.75" hole saw).

#3 - Test to make sure the coupling freely passes through the hole from the outside before attempting to install.

#4 - Insert a safety pin inside the pitless to ensure the elbow and slide do not separate during the installation of the pitless.

#5 - Thread the lift out pipe into the 1-1/2" blind hole in the top side of the pitless elbow (long enough to reach the hole for the pitless with enough pipe extending from the top of the casing, about 3-4 feet).

#6 - Lower the pitless assembly (pitless, nipple, and coupling) down the casing and insert the coupling through the predrilled hole.

#7 - Thread the 2" stabilizer pipe into the coupling (3-5 ft. min) to allow for soil compaction. This will support and hold the pitless securely to reduce the stress on the weld connection from the weight of the pipe column and submersible pump.

#8 - Align and secure both the lift out pipe and the service (discharge) pipe to ensure the pitless adapter is in the proper vertical and horizontal alignment.

#9 - Have a certified welder weld the coupling to the corrugated casing around the entire circumference to ensure that a watertight connection is made. This will prevent any surface water from entering the well and avoid any chance of contamination (proper breathing filters should be used to weld on galvanized casing - this is not ideal).

#10 - It is recommended to test the system for a significant duration to ensure there are no leaks at any connections prior to back filling (if this is done, make sure the discharge pipe is secured in position).

#11 - Back fill using proper back filling and soil compaction procedures. This will support the pitless from being tilted and stressing the well connection due to the weight of the pump.