Granular Activated Carbon (GAC) vs. Activated Carbon Block (CB) Water Filters

Granular Activated Carbon (GAC) vs. Activated Carbon Block (CB) Water Filters

Activated carbon filters are typically used as a complimentary filter to a pre-filter that removes the sediment. Carbon filters are designed to remove undesirable tastes, odors, and are very effective in removing free chlorine from water from a potable water source. They are also commonly used as finishing filters for Ultra-Violet (UV) and Reverse Osmosis (RO) water filtration systems. When selecting an activated carbon filter for these types of systems, you have two options: Granular Activated Carbon (GAC) or Carbon Block (CB). Both GAC and CB filters are manufactured using an activated carbon media, however this is where the similarities end.

Carbon filters remove contaminates by absorption, the greater the surface area, the more contact the water has with the carbon media. With more contact area, the length of time when the water is in contact with the carbon is also increased, increasing the effectiveness of the filter. Carbon block filters have a much larger surface area, which allows them to filter larger volumes of water while also being much more effective at filtering out tastes, odors, particles, heavy metals, and other contaminants. This does not mean that granular activated carbon filters are necessarily a bad choice. What is important is that you understand the differences and the tradeoffs between these two types of filters so you can make an educated decision. The information below provided the advantages and disadvantages for both granular activated carbon and carbon block filters.

WARNING: TEST YOUR WATER!

Before using carbon filters as a standalone filter, one must confirm that the water supply is “potable” or “safe for human consumption”. The water must be tested by a qualified water specialist to confirm the water is microbiologically safe. If the water supply is un-safe a water treatment or purification system, such as an RO or UV filtration system, to remove harmful contaminants present in the supply water will be required. The CB or GAC carbon filters are installed as secondary or finishing filters in order to remove undesirable odors and improve the taste of “safe” drinking water.

Granular Activated Carbon (GAC)

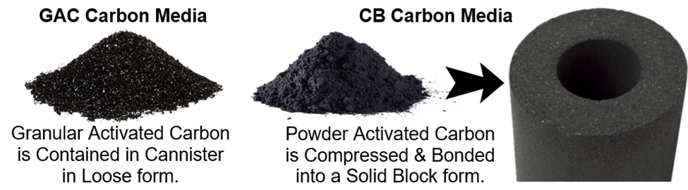

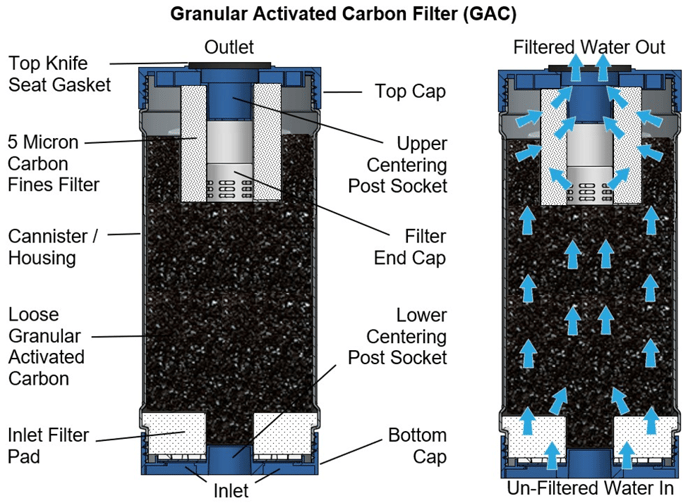

Granular activated carbon filters are manufactured using carbon that has been ground to a coarse granular structure which is contained loosely inside a cannister type cartridge. The loose nature of granular carbon in GAC filters means that they can provide a much higher flowrate than CB filters, which means that you can filter more water in less time. The tradeoff is that GAC filters are less effective than CB filters. However, the effectiveness of GAC filters can be increased by slowing down the flowrate using a flow control, increasing the amount of time that the water is in contact with the carbon to allow absorption of the contaminates. Granular activated carbon filters do have the advantage of lasting much longer than carbon block, although they do not provide the same level of contaminate removal as they are more prone to the following issues:

Granular activated carbon filters are manufactured using carbon that has been ground to a coarse granular structure which is contained loosely inside a cannister type cartridge. The loose nature of granular carbon in GAC filters means that they can provide a much higher flowrate than CB filters, which means that you can filter more water in less time. The tradeoff is that GAC filters are less effective than CB filters. However, the effectiveness of GAC filters can be increased by slowing down the flowrate using a flow control, increasing the amount of time that the water is in contact with the carbon to allow absorption of the contaminates. Granular activated carbon filters do have the advantage of lasting much longer than carbon block, although they do not provide the same level of contaminate removal as they are more prone to the following issues:

Channeling – Is a common issue with GAC filters, in the loose carbon bed as water travels through the filter finding the path of least resistance. When channeling occurs water bypasses carbon in the filter and the adsorption capacity is under-utilized.

Microbiological Growth / Dumping - In a loose bed of carbon, stationary pockets of water can develop due to changes in water pressure and flow rates. These pockets can result in bacterial growth and when these pockets collapse, "dumping" of the contaminated water into the water system can occur.

Carbon Block (CB)

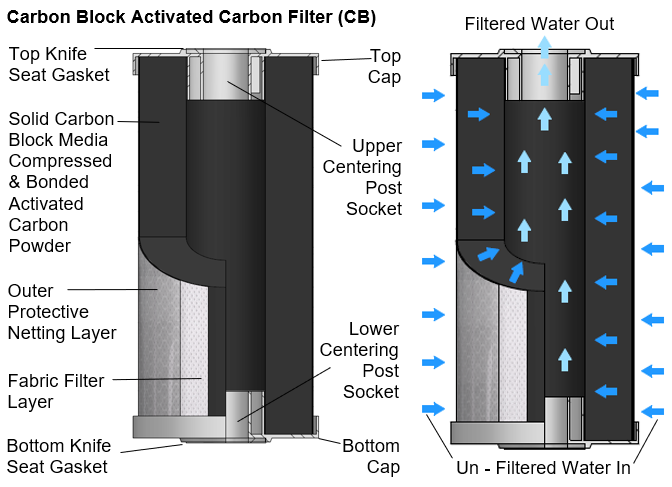

Carbon block filters are manufactured by grinding activated carbon into a fine powder. This powder is mixed with a food-grade binder, and the resulting mixture is heated up and compressed into a solid block. The carbon particles in a CB filter are 10 to 20 times smaller than the granular particles used in a GAC filter.

Carbon block filters are manufactured by grinding activated carbon into a fine powder. This powder is mixed with a food-grade binder, and the resulting mixture is heated up and compressed into a solid block. The carbon particles in a CB filter are 10 to 20 times smaller than the granular particles used in a GAC filter.

Since the carbon block filters are much more tightly packed, they can remove even the smallest particles and far more contaminants. Whereas some contaminants may be able to escape the loose granular carbon found in GAC filters. The compact nature of carbon block filters means that it takes water much longer to pass through the filter. This lowers flowrates and further increases the effectiveness of carbon block filters. This also contributes to a much higher contaminate removal rate than when using a GAC filter. The tradeoff for this improved performance is the reduction in flow rate.

Conclusion

Many water treatment and purification systems take advantage of both carbon block and GAC filters in various stages of the purification process for improvement of both taste and odor. This shows that granular activated carbon filters do have purpose, even if they do not provide the same level of contamination removal as the carbon block filters.

In situations where you must choose between the two, it becomes a choice on what is most important to you. A higher flowrate or better, more effective contaminate, taste, and odor removal. Hopefully, this information will make it easier for you to decide which type of carbon filter is best suited to meet your needs.

Finally, both GAC and CB carbon filters have a limited capability to remove contaminants from drinking water. The issues with GAC filters have been discussed, and even CB solid block filters do not remove total dissolved solids (TDS), bacteria, and viruses.

Additional types of Carbon Filters

There are other types of carbon cartridges which were not discussed in this article. They are covered in other articles which provide more detail on their specific purposes.

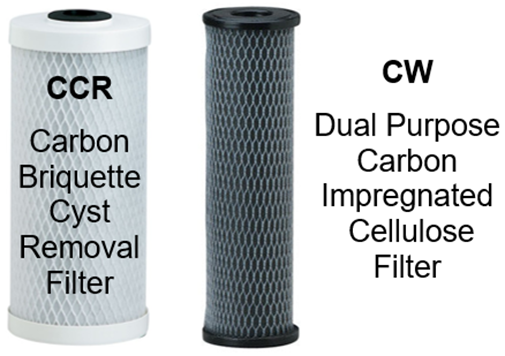

Carbon Briquette 'Cyst Removal' (CCR)

Solid carbon Briquette Cyst Removal filters (CCR) with a 0.5-micron rating have a solid block media. Third party certification and approval for cyst removal cartridges is important.

Solid carbon Briquette Cyst Removal filters (CCR) with a 0.5-micron rating have a solid block media. Third party certification and approval for cyst removal cartridges is important.

2-3/4" x 9-3/4" Individual:

https://boshart.com/product/2-3-4-x-9-3-4-individual/

2-3/4" x 20" Individual:

https://boshart.com/product/2-3-4-x-20-individual/

4-1/2" x 10" Individual: https://boshart.com/product/4-1-2-x-10-individual-5/

4-1/2" x 20" Individual: https://boshart.com/product/4-1-2-x-20-individual-11/

(CW) Carbon Impregnated Cellulose

Carbon Wrapped (CW) cartridges are sometimes referred to as a “PAC” type cartridge. Both of these are Powder Activated Carbon Wrapped Cartridges.

2-1/2" x 4-7/8" Individual: https://boshart.com/product/2-1-2-x-4-7-8-individual-2/

2-7/8" x 9-3/4" Individual: https://boshart.com/product/2-7-8-x-9-3-4-individual/

4-1/2" x 9-3/4" Individual: https://boshart.com/product/4-1-2-x-9-3-4-individual-2/

4-1/2" x 20" Individual: https://boshart.com/product/4-1-2-x-20-individual-12/

2-1/2" x 20" Individual: https://boshart.com/product/2-1-2-x-20-individual-8/