Electrical Tape: 5 Tips on How to Successfully Use it

Electrical tape. A simple product right? Well, it might be. When the electrical tape is properly applied, it can be a valuable asset for lots of different jobs like insulating motor lead connections. Having tips on how to accurately use a product can also save you some major frustrations.

In this blog post, we will first take a look at what electrical tape is and common uses. We will then dive into 5 tips on how to successfully use electrical tape to ensure a safe and trouble free installation. Let's get started.

For tips on how to effectively use thread seal tape, check out our blog, Thread Sealant Tape: Where and How to Properly Use it.

What is Electrical Tape?

Electrical tape is an economical general purpose insulating tape that has excellent resistance to moisture, abrasion and corrosion. It is used to insulate electrical wires, insulate other material that conduct electricity and make minor repairs to damaged wires. Electrical tape is commonly made from vinyl due to the elongation properties. There are also many additional purposes such as securing wire bundles.

5 Electrical Tape Tips

Tip #1: Select the appropriate grade

In cold conditions, you will need to select cold weather tape for better adhesion. Standard electrical tape can be used for all other applications like indoor settings. You should always pay attention to the min and max temperature ratings of the electrical tape to ensure you are using the correct one. You should also make sure that the tape is certified and is CSA and UL approved.

In cold conditions, you will need to select cold weather tape for better adhesion. Standard electrical tape can be used for all other applications like indoor settings. You should always pay attention to the min and max temperature ratings of the electrical tape to ensure you are using the correct one. You should also make sure that the tape is certified and is CSA and UL approved.

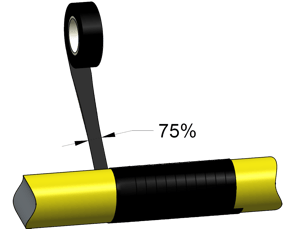

Tip #2: Half-lap the tape

Proper application of electrical tape is to half-lap, as shown in the picture, which results in a double layer of tape. The rule of thumb is to do a minimum of two half-lapped layers or one and a half times the thickness of the insulation of the wire that you are wrapping, whichever is greater. The tape should be thicker than the insulation, for added protection.

Tip #3: Stretch the tape as you wrap

Electrical tape works the best when it adapts to the object it is being applied to. When you go to apply your electrical tape to a cord or piece of wire, you should stretch the tape as you wrap. When the tape is stretched as its being applied, it will provide more insulation protection than when it is applied loosely. To create an effective insulation, you should wrap the tape between 75% of it's width to right before the breaking point. Doing this will ensure the tape will be able to withstand the elements. The last wrap should be applied with no tension to prevent flagging.

Tip #4: Don't use electrical tape as replacement for wire nuts

When you wire junction boxes or outlets, you should not use electrical tape as a permanent connection insulator. There is an electrical current that travels through bare wire copper and it produces heat. This can cause the electrical tape to degrade over time. Some electrical tapes may be able to stand the heat, but most electrical tapes are not designed for this type of application.

In the event that you are using electrical tape for a temporary pigtail splice, the electrical tape should be wrapped beyond the end of the wires, then folded backwards. This leaves a protective layer that resists cut-through.

Tip #5: Use self bonding tape for superior moisture resistance

Self bonding rubber tape or sometimes known as self fusing tape, can be used to insulate and moisture-seal low voltage (typically rated to 600 volts) electrical applications. Rubber tape bonds to itself when it is wrapped, there is no "sticky" side like normal tape. You should stretch the tape to 3/4 of the tapes original width to secure a moisture tight seal. Self bonding tape is made from rubber resin which provides durability, tear and abrasion resistance.

Always add two layers of vinyl electrical tape on top of the self bonding tape for additional abrasion resistance.

Electrical tape is a relatively easy product to use and with these tips, it is sure to be a trouble free installation. These tips will help you properly and safely use electrical tape for your next project. Remember to always verify the electrical and temperature ratings of the tape you are wanting to use before application.