Do I need to use the insert stiffener in my brass push-fit (BPF Series) fitting?

Yes & no! Now that you're even more confused let me explain…

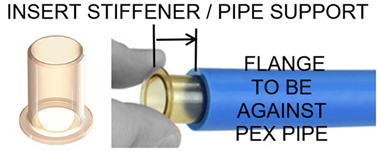

For starters, the BPF series fittings are shipped with the insert stiffeners (a.k.a. pipe supports) installed for convenience when making PEX connections and to reduce the risk of lost or missing inserts at the job site.

If you find a stiffener loose in the bag, no worries! From time to time a stiffener will come out of the fitting during shipping and handling. The stiffener can quickly and easily be reinserted by hand for installation in which the use of the stiffener is mandatory!

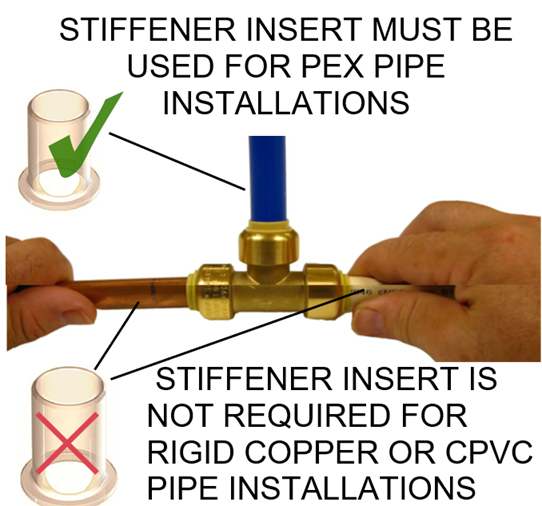

YES!– ALL PEX CONECTIONS MUST HAVE THE STIFFENER INSTALLED!

When installing PEX pipe (Type A, B or C) the stiffener MUST be installed in the end of the PEX pipe. The reason for this is that the stiffener will eliminate any out-of-roundness from the PEX pipe. Being shipped in a coil tends to cause some out of roundness.

The tube corrects this condition and supports the PEX in a round profile so that the O-ring can make a watertight seal with equal compression around the entire circumference. Oval pipe will have high compression on two sides and lower compression on the opposing sides. Oval pipe is also more prone to cutting an O-ring. For these two, reasons the use of the insert is critical!

TIP: There is no need to remove the stiffener from the fitting, simply follow proper pipe preparation procedures and push the PEX pipe into the fitting. The insert will slide into the PEX pipe. Make sure to mark the proper insert depth on the PEX pipe to ensure pipe is against the stop in the fitting. If the stiffener is loose in the bag, you can insert the stiffener into the PEX pipe and push the pipe and stiffener into the push fit fitting together.

NO! - COPPER & CPVC CONNECTIONS DO NOT REQUIRE STIFFENERS!

For copper or CPVC piping, the use of a stiffener is not required! Both CPVC and copper pipe are ridged and do not need the stiffener to retain their round profiles. Therefore, their use is optional!

Some installers leave the inserts in the fitting to save the time it takes to remove the stiffener from the fitting. The insert will do no harm from a connection standpoint; however they do reduce the open area through the fitting, causing a small degree of flow restriction. When installing a couple of fittings in a repair the flow restriction is minimal. However, if you are installing a high number of fittings in a piping run the flow restriction will add up and could potentially reduce the efficiency of the system.

Other installers always remove the stiffener when making a push fit connection to copper or CPVC piping, this ensures that there is no unnecessary flow restriction and provides optimal flow rates.

Note: It is less problematic to error in using a stiffener where it was not required than to fail to use a stiffener in a PEX connection. NEVER install PEX without the stiffener, the connection will be prone to leaking.

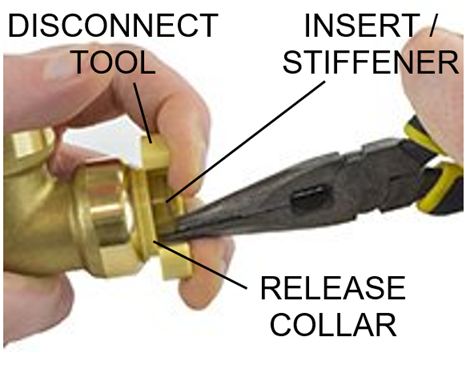

REMOVING A STIFFENER WHEN MAKING PUSH-FIT TO COPPER OR CPVC PIPE CONNECTIONS

The stiffener can be easily removed, but it must be done properly! Simply clamp onto the insert with needle nose pliers and push on the collar of the fitting with a disconnect tool to expand the gripper ring, the same as you would disconnect a connection. Slowly and gently pull the insert out past the stainless-steel gripper ring. NOTE: It should not take much effort at all, avoid pulling hard. If it does not come out easily it is likely caught on the gripper ring teeth and more pressure is required on the disconnect tool. Avoid excessive force which could damage the gripper ring.