Can I install a Flexcon Flow-Thru tank in a Boshart manifold?

Can I install a Flexcon Flow-Thru tank in a Boshart manifold?

Yes!

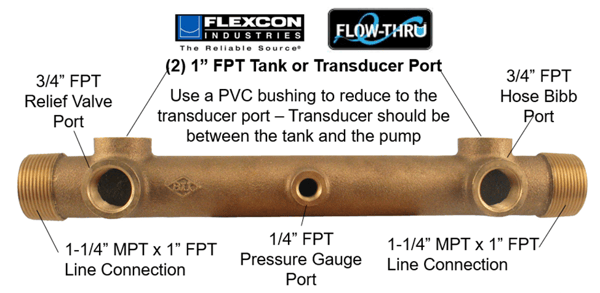

The part number 07M-125-10 which is a 1-1/4" MPT x 13-5/8" long manifold with two 3/4" FPT ports, two 1" FPT tank or transducer ports, and one 1/4" FPT accessory port are specially designed for use with Flexcon’s Flow-Thru™ tanks. They are also designed for systems or tank brands that have a 1” MPT tank (system) connection.

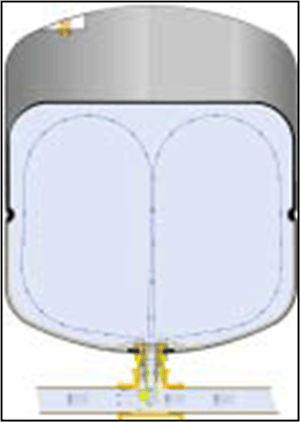

About Flexcon’s Flow-Thru Constant Pressure System Tank Design:

Today’s modern water systems deserve the best that the industry can offer. Ensure the safety and integrity of these systems by installing a Flexcon Flow-Thru™ tank product on every VFD installation. The unique patented designs provide total exchange of the water from the tank, thus preventing the possibility of stagnant water and dramatically reducing the potential for bacteria or algae growth.

The Flow-Thru™ tank’s two design configurations provide the utmost in installation flexibility.

The Circulation Problem:

In a standard water system that operates with a pressure switch and a 20 PSI differential between cut-in and cut-out, the water in the tank is flushed out and replenished on every pump cycle, thus greatly reducing the risk of stagnant water in the tank.

The Flow-Thru™ Solution:

Newer variable speed drive systems operate on much lower differential pressures. They turn the pump on at a system pressure drop of as little as 2-5 PSI and bring the pump up to speed very quickly. This means that the water stored in the pressure tank is never fully exchanged, but merely diluted with new system water. This creates the possibility of stagnation.

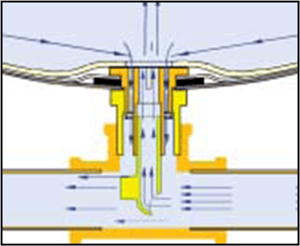

Technology:

Technology:

The patented Flow-Thru™ connection features an innovative windvane insert that diverts system water into, and more importantly, out of the tank while the pump is running. This flushing action assures that the water in the tank remains fresh and eliminates the possibility of stagnant water during normal system operation.

Total Recirculation:

Flexcon’s patented Flow-Thru™ technology assures total recirculation of the tank’s water content within 50 gallons of system demand. The Flow-Thru™ tank continues to circulate water through the tank whenever the pump is operating.