Can a PUSH-FIT fitting connection be made wet or dry?

Yes! PUSH-FIT Fitting Connections can be made Wet or Dry!

BPF Series (Brass-Push-Fit) Fittings are a real time saver, easy to install requiring very few tools, NO FLAME or SOLVENTS, and they are a great solution for making wet connections and repairs.

Brass Push-Fit Fittings make secure connections. First the tube or pipe is inserted into the fitting. It passes through both a release collar and a stainless-steel gripper ring. The gripper ring has internal teeth that flex outward and grip into the O.D. of the tube. The tube or pipe is then inserted further through an O-ring protector to align the tube. The pressure seal is made by an Ethylene Propylene Diene Monomer (EPDM) O-Ring which is compressed between the fitting wall and the tube. The tube passes by the O-ring to the tube stop. NOTE: The tube must pass through the O-ring and against the tube stop to make proper connection. BPF Series Push-Fit Fittings can be used with pipe or tubing certified to the following specifications: PEX (ASTM F876, CSA B137.5), COPPER (ASTM B 88), & CPVC (ASTM D 2846, CSA B137.6).

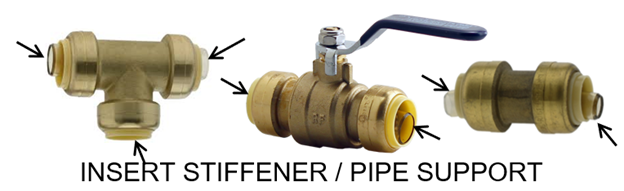

The fittings are shipped complete with an insert (stiffener) that is inserted into PEX piping for added support and to keep the pipe O.D. round. This ensures the O-ring makes a positive seal on the outside of the PEX pipe. Stiffener inserts are not required when installing Copper or CPVC piping, and they can be easily removed.

Making Push-Fit Fitting Connections:

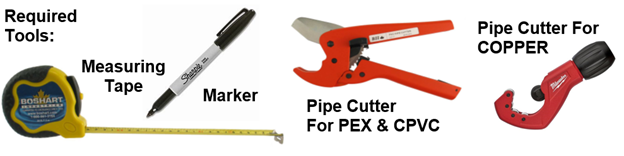

STEP 1. - Select the correct size fitting and piping for the installation. It is extremely important to check that both the fittings and pipe are in a good, clean condition, free of damage and foreign objects.

STEP 2. - Use proper pipe cutting tools such as rotary tube cutters for copper pipe or PVC pipe cutter for PEX or CPVC piping. The use of a hack saw is not recommended as it will create burrs. The tube must be cut so the ends are square and cut ends must be inspected to make sure that they are free form burrs or damage.

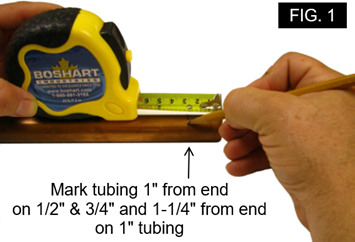

STEP 3. Scribe or mark the outside of the pipe with the proper insert depth which is 1" (25.4mm) from the end of 1/2" & 3/4" pipe and 1-1/4" (31.75mm) from the end on 1" piping (see FIG. 1). This mark is used as a visual guide to ensure that the pipe is inserted all the way to the stop. Failure to insert the pipe against the stop will not produce a secure connection.

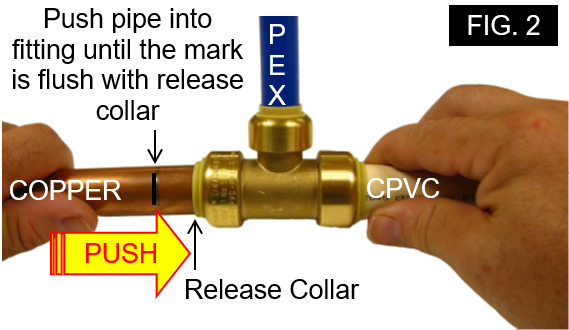

STEP 4. - Insert the pipe through the release collar, gripper ring, and O-ring. Push the pipe firmly until the pipe is against the internal pipe stop.

STEP 5. - To ensure that the pipe is correctly inserted, check that the depth mark is flush with the edge of the release collar (see FIG. 2).

Disconnecting a PUSH-FIT Connection:

Disassembly of a BPF connection can only be accomplished by using a disconnect tool or clip to apply pressure to the release collar. This spreads the gripper ring teeth, releasing their grip on the pipe. This action releases the pipe, allowing it to be removed from the fitting.

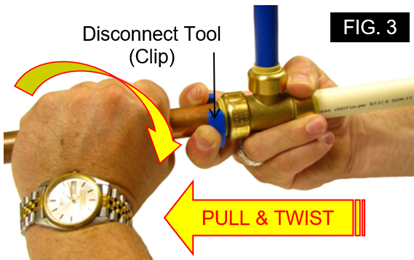

STEP 1. - Snap the disassembly tool or clip around the pipe with the recessed face against the release collar (see FIG. 3).

STEP 2. - Apply pressure on the disassembly tool or clip, pushing the clip against the release collar, then gently pull the pipe out of the fitting with a slight twisting action (see FIG. 3).

STEP 3. - Always check the fitting and tube end for damage. The fitting and pipe must be 100% free of damage and the piping must not have any scratch marks on the outside diameter. If the pipe is damaged or scored, then cut off the damaged section or use a new section of piping for re-assembly.