BF Series Brass Flare Fitting Information

BF Series Brass Flare Fitting Information

BF Series Brass Flare Fitting Information

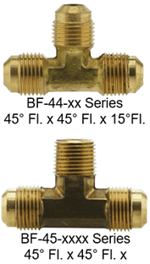

BF series fittings are commonly machined from CA360 brass bar-stock (bar stock fittings) or forged from C37700 alloy (forged fittings). The 45° SAE flare is the most common flare fitting used in the HVAC industry today. SAE 45° flare connections are commonly used in wide variety of applications. They are ideal for joining high pressure hydraulic tubes in refrigerant lines connecting air-conditioner and heat-pump components, heavy machinery, and industrial, construction, and pneumatic equipment to transfer fuel oil, fertilizers, and other fluids and chemicals not corrosive to brass and tubing materials.

**These fittings are not suitable for direct burial or gas applications. Some jurisdictions/ gas codes do not permit the use of alloys with less than 80% copper in underground applications. These fittings do not qualify. The qualified installer, and end user, should confirm with local codes and AHJ (Authority Having Jurisdiction) if fittings are suitable for the application. We suggest you do not use these products for direct burial or gas applications.

SAE 45° flare fittings provide a dependable seal that is resistant to damage from vibration and is an excellent choice for plumbing oil and refrigerant lines. Flare connections have remarkably high resistance to being pulled apart and can be disassembled and reassembled repeatedly. However, the biggest advantage they have over other plumbing connections is the safety factor provided when working with fluids such as in oil lines, since no open flame is required as with soldered connections.

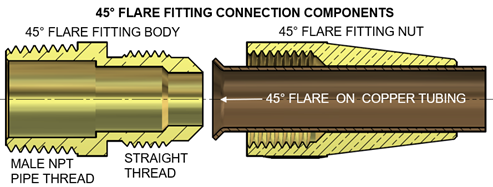

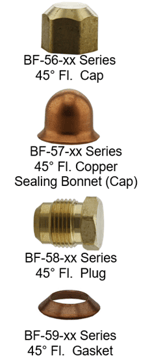

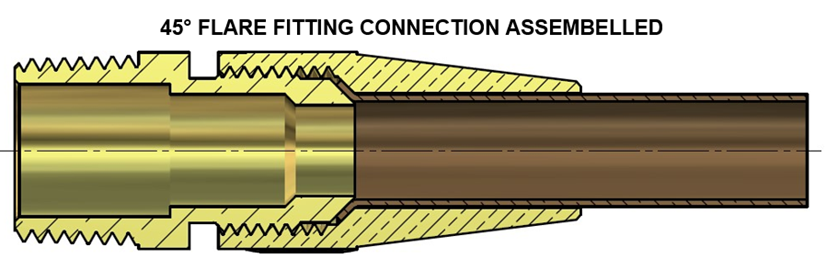

The main components to the flare fitting connection are the fitting body, the flared tube, and the nut. These three parts work together to create a metal-to-metal seal when the nut draws the flared tubing and fitting body together.

The main components to the flare fitting connection are the fitting body, the flared tube, and the nut. These three parts work together to create a metal-to-metal seal when the nut draws the flared tubing and fitting body together.

Temperature / Pressure Ratings

Temperature Range: -65°F to 250°F (-54°C to 121°C) at maximum operating pressures.

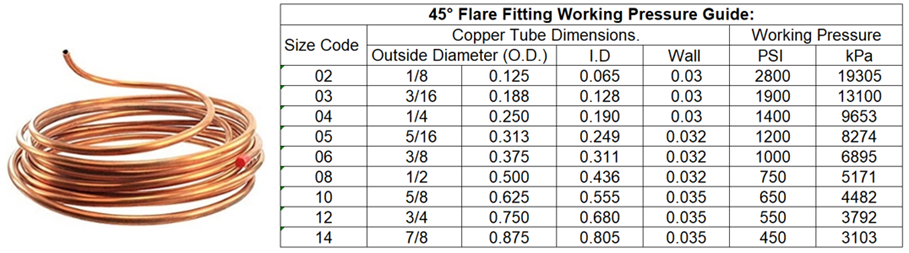

SAE 45° flare fittings are used for low to medium pressure applications.

WARNING: Working pressure, temperature ranges, and type of tubing used are all crucial factors. The following table is to be used as a guide only for selection and is based on using copper tubing.

Not for Potable Water!

Not for Potable Water!

45° flare fittings are not commonly used to plumb water lines. They would be suitable from a design standpoint however they are rarely used in residential potable water plumbing applications. This is because it does not warrant the use of these higher cost, labor-intensive connections although they provide a more robust joint. The reasoning behind this is that residential water pressures are typically 60 PSI or less, nor will a leaking water line fuel a fire or lead to an explosion. For this reason, we do not offer them in a NL (No-Lead) version with NSF-372 certification.

Flared fittings offer a high degree of long-term reliability and are used in mission-critical and inaccessible locations. Use flare fittings in applications that involve:

Flared fittings offer a high degree of long-term reliability and are used in mission-critical and inaccessible locations. Use flare fittings in applications that involve:

-

-

-

- Movement

-

-

- Low to medium vibration levels

- Fuel Oil

- Higher pressures than a flareless / compression type fitting can handle

Tubing

45° flare fittings can be used with copper, aluminum, and welded steel hydraulic tube that can be flared.

Typically flare connections are made with the soft copper tubing that is shipped in coils. This tubing is particularly suitable for connecting thin- to medium-diameter wall tubing which is commonly used for fuel-oil lines. For practical purposes rigid copper tube is not commonly flared as rigid copper is hard and is more prone to tearing in the flaring process unless it is annealed by heating with a torch and allowed to cool slowly. Therefore, rigid copper is typically used with either soldered joints or compression type fittings.

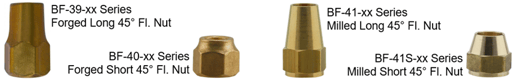

Flare Nuts

Use long series milled BF-41 or forged BF-39 flare nuts for vibration.

The qualified installer, and end user, should confirm with local codes and AHJ (Authority Having Jurisdiction) if fittings are suitable for the application. We suggest you do not use these products for direct burial or gas applications.

Always use forged nuts for extreme cold.

Other Types of Flare Fittings

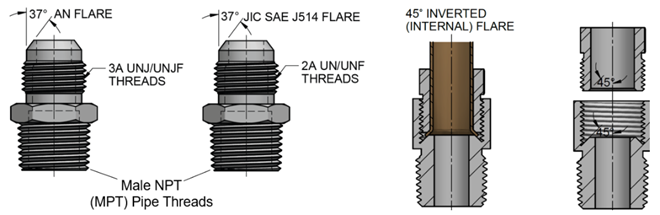

There are three other common types of flare fittings systems, 45°-degree inverted flare, 37° AN style, and the 37° JIC system. 45° inverted flare hydraulic fittings are widely used in hydraulic brakes, power steering, fuel lines, and transmission cooler lines. Inverted flare also provides excellent vibration resistance. However, the seats and threads are internal and protected. You may also see 30° flare fittings.

The AN / JIC style has a higher-pressure rating for a given size tubing. SAE and AN/JIC fittings are completely incompatible due to the different flare angle. The 37.5° angle is the industry standard in automotive work. If you are working on brake lines, you need a different flare tool. JIC stands for the Joint Industries Council, and AN stands for Air Force – Navy Aeronautical Design Standards.

CAUTION: It is important not to mix the different types of fittings.

CAUTION: It is important not to mix the different types of fittings.

WARNING: Improper selection and or use of the product could result in product failure, property damage, and could cause personal injury or death.

The type of fitting you choose depends on your application and all applicable regulations, both national and local plumbing or building codes. If you are not sure whether the product meets all the requirements, we strongly recommend that you reach out to the AHJ (Authority Having Jurisdiction) over the project for professional technical advice.

Due to the wide range of applications and operation conditions for the product, the qualified system designer / end user is solely responsible for making the final selection of the product and assuring that all applicable codes, performance and safety requirements are met for the application through their analysis and testing.

Additional Resources:

Copper Development Association, Inc. (USA) https://www.copper.org/

Copper Development Association - 9. Flared Joints https://www.copper.org/applications/plumbing/cth/cth_8flrdjts.html

Canadian Copper & Brass Development Association http://coppercanada.ca/