Are Your Stainless Steel Ball Valves “Food Grade”?

We carry three series of stainless steel ball valves. They are SSBV304-XX, 316 stainless SSBV1000-xx, and 316 stainless SSBV2000-XX. These valve series do not have any “Food Grade” certification.

That said these 304 and 316 grade stainless steel ball valves, as well as other S.S. products such as Class 150 stainless pipe fittings, nipples and ready cut pipe, are commonly used in food processing applications.

The final decision as to a products suitability for a particular food application must be looked at on a case-by-case basis and it is the sole responsibility of the plant inspector or AHJ (Authority Having Jurisdiction) over the project to decide if these products are suitable for the specific application. They will be suitable for many but not all applications.

There will be some food processing applications that will require special sanitary ball valves a.k.a. cavity filled ball valves. We do not carry these valves.

There will be some food processing applications that will require special sanitary ball valves a.k.a. cavity filled ball valves. We do not carry these valves.

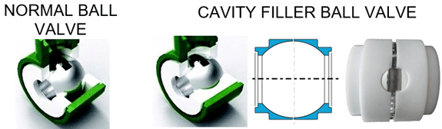

Cavity Filled Ball Valves

Cavity filled ball valves have a seat design which fills the gap between the ball and the valve body all the way around. This eliminates the possibility of contamination due to buildup of starches and slurries over time, since they are difficult to clean out during washdown. The cavity filler seat prevents the fluid from getting into this cavity which is open in normal type ball valves.

Normal type ball valves allow fluid media and debris to be trapped in the inner-body cavity, which is nearly impossible to clean and can result in damage to the seating surface and even blocking of valve operation. This is also a problem in processing products such as reactive monomers like butadiene and styrene which tend to polymerize or ferment within the cavities of the valves.

Cavity filled ball valves offer excellent performance in sanitary systems. This includes food and beverage, micro brewing, pharmaceutical, process gas, and other industrial applications.

What we can provide is the product data sheets which outline the materials break down for the valve components as well as the composition of the 304SS and 316SS material as required.