Are your Sch. 80 PVC pipe nipples seamless?

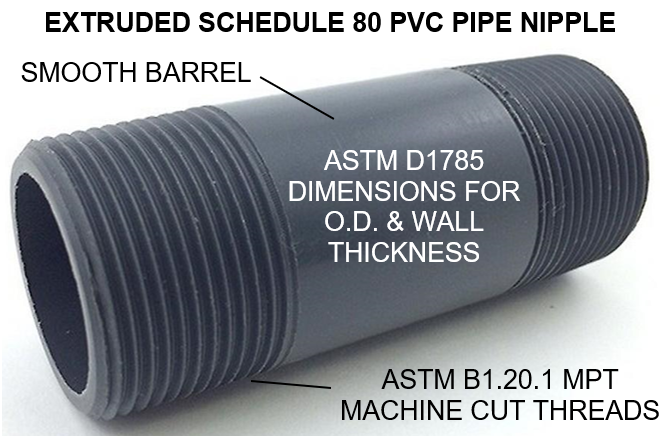

Yes! - The 880 Sereis PVC pipe nipples sold by Boshart are manufactured from extruded pipe, the threads are cut in the same way that steel, red brass, and stainless-steel nipples are made. Extruded (seamless) PVC nipples are superior to injection molded PVC pipe nipples in several ways. Injection molded PVC nipples are typically less expensive and may be suitable for many applications, but not all!

Boshart does not offer the molded PVC nipples, here are three reasons why...

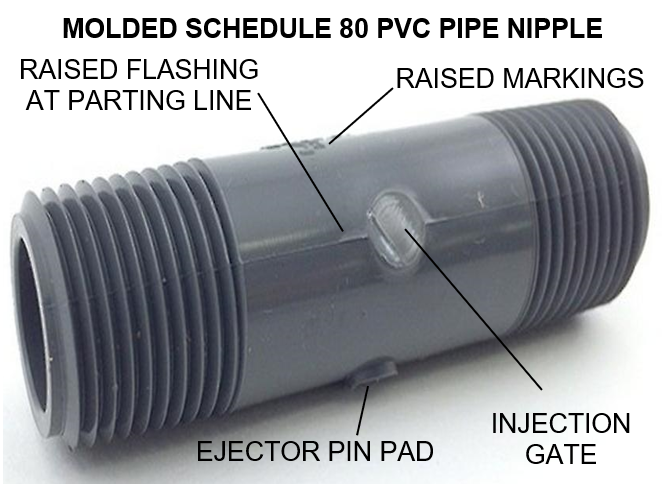

#1 - Extruded PVC nipples are extremely strong and do not have a knit line which all injection molded parts have. A knit line in a plastic injection-molded part is created when two separate plastic flows meet within the mold and "resolidify" along their interface. Depending on the resin, resin temperature, mold temperature, and filling speed, knit lines can vary from virtually invisible to something that looks like cracks in the plastic. And in some cases (e.g., long thin features) the knit lines can have reduced mechanical properties and be a cause of part breakage. So, for reasons ranging from cosmetics to functionality, it is important to evaluate whether a less expensive molded nipple is suitable.

#2 - The Outside Diameter (O.D.) of extruded PVC pipe is controlled by pipe manufacturing standards ASTM D1785 and eliminates issues where some manufacturers of injection molded fittings may not control the dimensions as closely as required for high quality solvent weld connections, resulting in a poor fit when solvent welding a T.O.E. nipple into a PVC socket. A T.O.E. nipple is a nipple that is threaded on one end. Installers commonly cut a T.B.E. (Threaded Both Ends) to produce two T.O.E. (Threaded One End) nipples to make a transition from solvent weld PVC to a threaded valve or fitting. Molded nipples, (from some manufacturers) have been found to be too small, too large or out of round.

#3 - It is common to find that injection molded nipples have a raised parting line seam, raised part marking, indents, raised areas where the mold ejector pins push the part from the mold, and a rough surface where the gate is where resin is injected. These surface imperfections, as with improper O.D., can result in a poor-quality joint, potentially resulting in a connection failure.

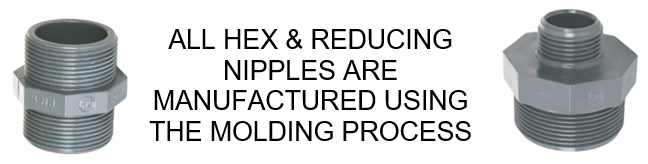

NOTE: All PVC HEX and REDUCING nipples are made using the molding process, since it is not possible to produce these odd profiles from extruded pipe.