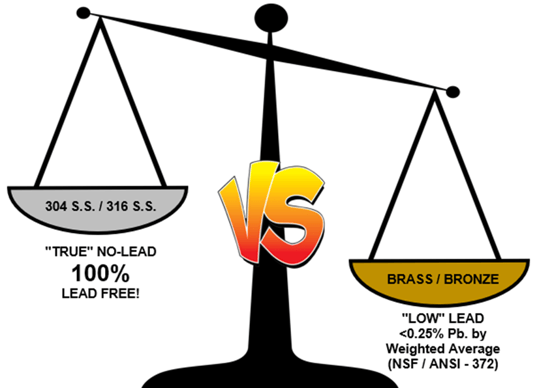

Are products certified to ANSI/NSF-372 truly No-Lead (NL) or Lead-Free (LF)?

The answer is both YES and NO. It depends entirely on the material from which the product is manufactured. Very confusing to say the least! In this article we will explain why the misleading NL (No-Lead) or LF (Lead-Free) terminology is commonly used across the plumbing industry in both the U.S.A. and Canada.

It all started when the California Assembly Bill 1953 (AB1953) was signed into law in September 2006. This legislation required lead reduction in products to a weighted average of no more than 0.25% in pipes, fixtures, and fittings. This reduction to the allowable lead content was eventually adopted in a revision to the SDWA (Safe Drinking Water Act) in 2014. In this revision, the lead content was reduced from 8% to <0.25% Pb (lead) by weighted average. Some states required that products must be 3rd party certified to ANSI/NSF-372 to confirm that the product indeed meets the reduced lead criteria.

It all started when the California Assembly Bill 1953 (AB1953) was signed into law in September 2006. This legislation required lead reduction in products to a weighted average of no more than 0.25% in pipes, fixtures, and fittings. This reduction to the allowable lead content was eventually adopted in a revision to the SDWA (Safe Drinking Water Act) in 2014. In this revision, the lead content was reduced from 8% to <0.25% Pb (lead) by weighted average. Some states required that products must be 3rd party certified to ANSI/NSF-372 to confirm that the product indeed meets the reduced lead criteria.

Unfortunately, Boshart’s suggestions to use more accurate “LOW LEAD” terminology instead of the NL or LF descriptions went over like a lead balloon (PUN intended). NL or LF were officially adopted as the description for products meeting this reduced lead content requirement despite the fact they are not truly lead-free or no-lead. These industry wide descriptions are not only misleading, but also cause great confusion when dealing with other materials which are truly lead-free such as 304 SS, 316 SS, Nylon, Poly, and PVC for example.

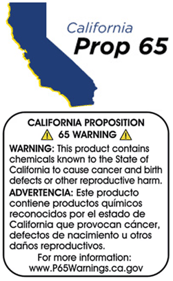

California PROP 65

Another area of confusion is why the NL and LF products like brass (yellow brass), red brass, and bronze have the Proposition 65 warning labels. The reason for this labeling requirement is because these materials are allowed to have an extremely low % of Pb. Specifically, they may have a level under the NSF / ANSI-372 No-Lead requirement of <0.25% Pb. However, a California PROP 65 warning label must be applied if there is any trace of a chemical on the Prop 65 list of hazardous chemicals. Therefore, brass or bronze products, although referred to as NL or LF, must be labeled due to their lead content.

Another area of confusion is why the NL and LF products like brass (yellow brass), red brass, and bronze have the Proposition 65 warning labels. The reason for this labeling requirement is because these materials are allowed to have an extremely low % of Pb. Specifically, they may have a level under the NSF / ANSI-372 No-Lead requirement of <0.25% Pb. However, a California PROP 65 warning label must be applied if there is any trace of a chemical on the Prop 65 list of hazardous chemicals. Therefore, brass or bronze products, although referred to as NL or LF, must be labeled due to their lead content.

Canada CSA / ASME Standards – Low Lead

In Canada the low lead terminology is more prevalent, however the same low lead content requirements introduced in the U.S., which become law there on January 4, 2014 under the SDWA, apply in Canada. It is required that the level of lead be reduced to no more than a weighted average lead content of 0.25% on wetted surfaces when evaluated for pipes, valves, pipe fittings, and plumbing fittings, anticipated to convey or dispense water for human consumption through drinking or cooking.

In Canada the low lead terminology is more prevalent, however the same low lead content requirements introduced in the U.S., which become law there on January 4, 2014 under the SDWA, apply in Canada. It is required that the level of lead be reduced to no more than a weighted average lead content of 0.25% on wetted surfaces when evaluated for pipes, valves, pipe fittings, and plumbing fittings, anticipated to convey or dispense water for human consumption through drinking or cooking.

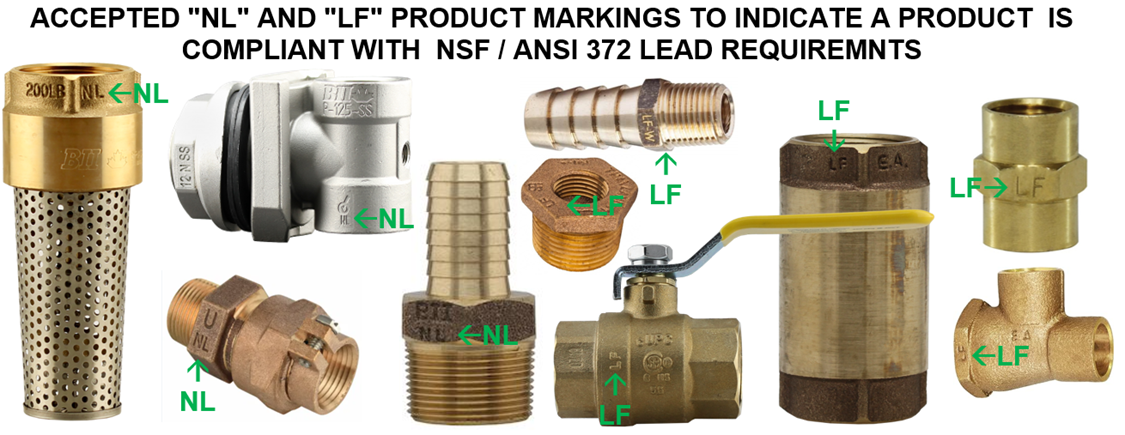

The product is typically marked with NL or LF to indicate compliance. The key difference in Canada is that the new reduced lead requirement is being adopted into the CSA / ASME standards as they are updated.

Health Canada has indicated that work is ongoing in terms of including the low lead requirements in the necessary standards.

The new versions of ASME A112.18.1/CSA B125.1 and CSA B125.3 standards for plumbing fittings specify the test method in NSF 372 for the low-lead evaluation requirements. Backflow valves (CSA B64 series), pressure pipes (CSA B137), drinking water treatment (CSA B483), flexible connectors (ASME A112.18.6/CSA B125.6), and other product standards also will reflect the <0.25% Pb by weighted average as per NSF / ANSI – 372.

Why test and certify a product that contains zero lead?

To legally sell products in some states, they must be certified to confirm that the product has <0.25% Pb by weighted average, as per the revision of the SDWA that became effective January 4, 2014. This revision reduced the allowable lead content from 8% to 0.25%. The lead content testing to ANSI/NSF-372 Testing Protocol on brass and bronze alloy products makes sense as these alloys typically have lead content higher than the allowable limit and are unfortunately categorized as “NO Lead” or “LOW Lead” even though they do contain it.

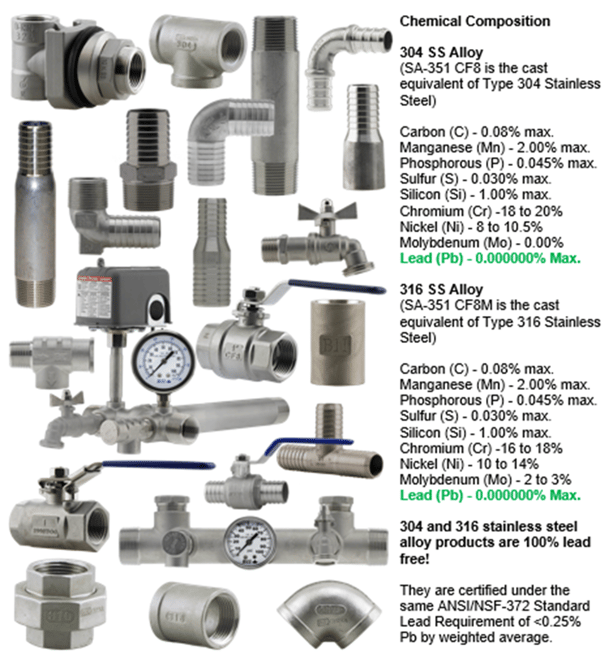

In some instances, it is still necessary to test and certify other materials such as 304/316 Stainless Steels and many plastic valves, fittings, and other plumbing components which always were and continue to be TRULY LEAD FREE (0.000% Pb content). As crazy as it may seem, the same ANSI/NSF-372 certification and testing protocol was forced on products manufactured from materials and alloys that were 100% lead free by nature to legally sell in some areas of the USA. This defies common sense and makes the issue very confusing, needlessly increasing the cost. Unfortunately, it has caused many to believe that 304/316 SS alloys have lead in them, which is not the case.

Products manufactured from C2300 RED Brass, such as brass pipe, brass pipe nipples, and swaged insert adapters/couplings for PE pipe have always been manufactured from this alloy which has an exceptionally low lead content of 0.05%. This is well below the allowable maximum lead content of <0.25% Pb. These products did not require any material change to meet the ANSI/NSF-372 certification and testing protocol.

Additional Resources:

https://doh.wa.gov/sites/default/files/legacy/Documents/Pubs/331-473.pdf

https://www.nsf.org/knowledge-library/nsf-ansi-can-372-technical-requirements

https://www.hpacmag.com/features/the-lowdown-on-low-lead/

https://www.ciph.com/page/CACP_Update

https://www.canada.ca/en/health-canada/programs/consultation-lead-drinking-water/document.html

https://www.p65warnings.ca.gov/about/frequently-asked-questions

https://oehha.ca.gov/proposition-65/proposition-65-list

https://support.boshart.com/why-do-no-lead-nl-products-have-prop-65-warning-labels