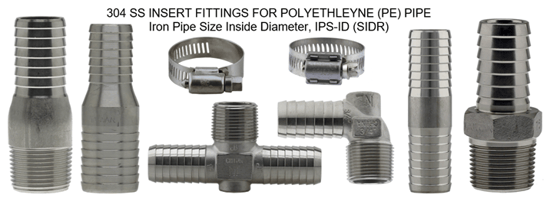

Are 304 stainless steel insert fittings suitable for direct burial?

The quick answer in the vast majority of situations is yes! However, in some geographic areas where salts, such as sulphates and chlorides, are present in the soil and if the soil in the area is known to be aggressive with a low pH value, the use of 304SS may not be the best option. Let’s dive in a little deeper.

BACKGROUND

Damp or direct burial installations require the most corrosion resistant materials available. Over the years the go-to materials emerged as bronze and stainless steel. The use of stainless steel has grown in popularity since the introduction of the SDWA (Safe Drinking Water Act) in 2014 due to the extremely high cost of no-lead bronze alloys. 304 SS insert fittings have been very successfully used to install buried water service lines and in water well installations and are a good choice due to their high corrosion resistance.

Bronze insert fittings are also an excellent choice for direct burial. It is important that you do not confuse brass alloys with the superior bronze alloys as insert fitting topics overlap into PEX fitting territory. PEX fittings are only available in brass (there is no bronze PEX fitting option available). One must be sure of the alloy, copper, and zinc content when selecting either PE pipe insert fittings or PEX fittings for direct burial applications as there are lower cost brass inserts sold. If brass is selected, make sure to use dezincification “resistant” brass (DZR brass). Stainless steel PEX fittings are gaining in popularity due to their corrosion resistance.

To address the 304-insert fitting question we must start by stating that the AHJ (Authority Having Jurisdiction) always has the final say on whether a given product or material is suitable for the specific application or project in question. In addition, one must make sure to adhere to all the applicable national and or local plumbing and building codes for the area.

To address the 304-insert fitting question we must start by stating that the AHJ (Authority Having Jurisdiction) always has the final say on whether a given product or material is suitable for the specific application or project in question. In addition, one must make sure to adhere to all the applicable national and or local plumbing and building codes for the area.

Unless the AHJ or a code rules the use of stainless steel fittings out, 304 stainless steel has been used and has performed extremely well in buried water service lines, water well, and a wide range of plumbing applications for many years. Let’s take stainless steel gear clamps as a prime example.

Regardless of the insert fitting material (which are detailed below) used in the installation of a buried water line, ALL 300 Series stainless steel clamps have been used to secure the polyethylene (PE) pipe in these direct burial applications.

CAUTION: Clamps or fittings produced from 200 / 400 grades of stainless steel are not recommended for direct burial.

While one solution will not fit all applications, the information below will be useful in making an educated decision on which material is best suited for direct burial in your geographic location.

Materials that have been used for direct burial:

Hot Dipped Galvanized / Zinc Plated Insert fittings – These fittings have been used and have been known to last a very long time in some areas depending on the soil conditions. However, they are not recommended for direct burial applications.

Brass Fittings – These fittings have also been used and may last a very long time depending on the water and soil conditions. However, brass alloys with more than 15% zinc content (yellow brasses) are subject to dezincification and are not recommend for a direct burial application.

Bronze Fittings / Red Brass Pipe – These alloys have a high copper content (81-86% Cu) and less than 15% zinc content so they are not affected by dezincification. They by far provide superior corrosion resistance compared to both hot dipped galvanized / zinc plated insert fittings and high zinc content brass fittings. Bronze has been proven time and again as the best material in this regard when aggressive soil and water conditions are present.

304 Stainless Steel Fittings / Pipe - 304 Stainless Steel fittings provide superior corrosion resistance and are not susceptible to dezincification which is a concern with brass fittings. 304 S.S. is a much better choice than brass for underground installations. However, in aggressive soils they too can be adversely affected by the soil aggressive conditions, therefore 304 SS components must be wrapped with a silicone pipe wrap to protect against accelerated corrosion by the soil. Failure to wrap the fitting in any underground application will void the warranty if the failure is soil related.

Stainless Steel Clamps - A 300 grade stainless steel clamps are recommended for securing PE piping to the insert fittings due to their high corrosion resistance. They have performed very well, proven by the test of time. Based on the track record of ALL 300 Series clamps, there should be peace of mind. However, there are areas were soil conditions have a pH value less than 4.5 and there is a presence of chlorides and stray currents. These could have adverse effects on stainless steel, which needs to be considered.

Reference:________________________________________________________

https://www.ibexaustralia.com.au/resources/stainless-steel-underground

If salts such as sulphates and chlorides are present in the soil and is known to be aggressive, the pH value of the soil in which the stainless steel is buried plays a major role in corrosion and degradation. More acidic soils may represent a serious risk to common construction materials including some stainless-steel grades. Soils acidity is produced by mineral leaching, decomposition of acidic plants, industrial wastes, acid rain and certain forms of micro-biological activity. If the pH level is greater than 4.5, corrosion of buried stainless steel due to acidity is unlikely. As a rule of thumb, well-drained soils are generally found to be less corrosive than poorly drained ones. Backfilling pipe ditches with sand provides reliable long-term protection in corrosive soils such as silt.

_________________________________________________________________

316 Stainless Steel – Also in the 300-grade series stainless family. However, it is superior in corrosion resistance due to the addition of 2-3 molybdenum and should be seriously considered for installations if the soil is aggressive or has a high saline or chloride content. 316 SS is not always an option as many types of fittings are not available in the higher cost 316 material.

Alternative Solutions

If the corrosion of 304 SS is a concern due to your local soil conditions, the use of BRONZE fittings (not brass) or a PLASTIC material should be considered. One must consider that plastic fittings will not have the high impact resistance of metal fittings so more care must be taken when back filling.

Nylon – Nylon is one of the toughest materials, it is great for water well and underground (trench) applications and is the most durable plastic option for back filling. It is not suited for exposure to sunlight.

Poly - Poly is less durable than nylon or PVC, it is economical, but would not be the most suitable for direct burial.

PVC - PVC is suitable for direct burial and is often used in irrigation applications since it is not affected by ultraviolet exposure.

Additional Related Information:

If you were to research about the direct burial of PEX water lines, the plumbing industry would suggest that when burying PEX piping, an unbroken line of PEX is ideal, and that plastic PEX fittings should be used in areas known to have aggressive water or soil when a fitting is necessary. Stainless steel pinch clamps or rings should be used rather than copper crimp rings due to their increased corrosion resistance. This is another example where the industry endorses the use of stainless steel in direct burial applications.

The links below are some resources for relevant information:

https://www.worldstainless.org/applications/architecture-building-and-construction-applications/

Conclusion

As mentioned above 304 SS is used successfully in many direct burial applications, however it is not suitable for every direct burial application due to aggressive water and soil conditions in some areas. These factors must be taken into consideration when making product selection decisions. Your plumber or local water works professionals will have the best knowledge of local soil and water conditions to provide insight as to which materials are best to use. In addition, they should be aware of any local requirements, it's always a good idea to check with local authorities before work begins - some codes specify the type of pipe material allowed based on the length of the service line, the incoming pressure, or other factors.

We trust this information has been helpful to you in making an educated decision on material selection.