BOSHART Industrial Pitless Unit Pressure Rating.

What is the pressure rating of a BOSHART Industrial Pitless Unit?

What is the pressure rating of a BOSHART Industrial Pitless Unit?

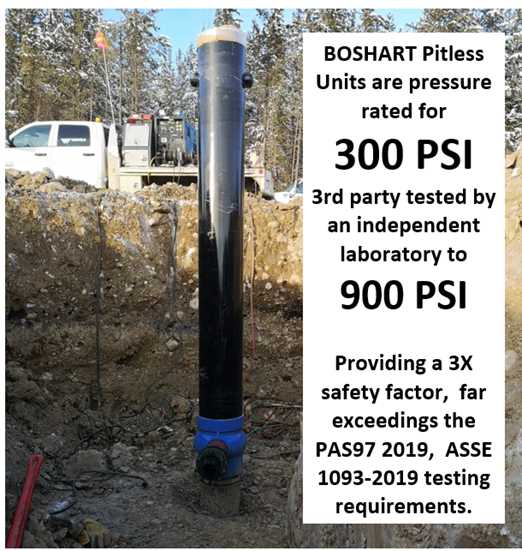

The BOSHART Pitless Units are pressure rated for 300 PSI with a 3X safety factor, the pressurized zone / O-ring seals for both Normal and Flowing Well Pitless Units has been 3rd party tested by an independent laboratory to 900 PSI. This pressure far exceeds the PAS97 (2019 / ASSE 1093-2019) testing requirement of 150 PSI test pressure with out any safety factor requirement under PAS97-20 19 / ASSE 1093-2019).

Flowing Well – Cable Seals

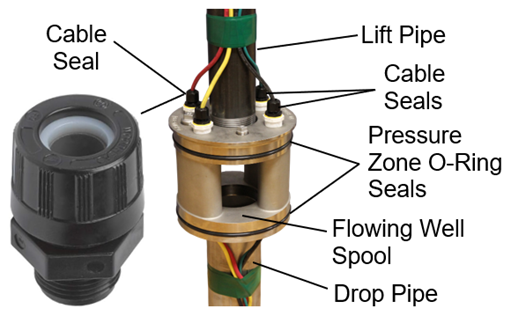

Flowing Well installations have an additional component which needs to be considered. Cable seals are used to ensure a watertight seal on each power conductor and or grounding cable to seal the water below the spool to prevent the filling of the upper barrel with water. These seals need to seal against the internal well pressure created by the artesian / flowing well, the pressure at the / Pitless spool, located near the surface just below the frost line is significantly lower than the pressure created by the submersible water pump. For example, the cable seal may only be subjected to 10 PSI, the pressure created by flowing wells will vary so no two wells will be the same. We have rated at 250 PSI with a 3X safety factor, the seals have been hydrostatic tested to 750 PSI.

Flowing Well installations have an additional component which needs to be considered. Cable seals are used to ensure a watertight seal on each power conductor and or grounding cable to seal the water below the spool to prevent the filling of the upper barrel with water. These seals need to seal against the internal well pressure created by the artesian / flowing well, the pressure at the / Pitless spool, located near the surface just below the frost line is significantly lower than the pressure created by the submersible water pump. For example, the cable seal may only be subjected to 10 PSI, the pressure created by flowing wells will vary so no two wells will be the same. We have rated at 250 PSI with a 3X safety factor, the seals have been hydrostatic tested to 750 PSI.

Additional Resources:

https://support.boshart.com/how-do-i-properly-install-my-pitless-adapter

https://support.boshart.com/how-do-i-install-a-spool-type-industrial-pitless-unit

https://support.boshart.com/do-the-spool-type-industrial-pitless-adapter-units-have-hold-down-hooks

https://support.boshart.com/how-do-i-install-a-wtcl-c-series-industrial-well-cap

For information on the Pitless units see the "Municipal and Industrial Pitless Well Systems Booklet."

For details on the well cap part numbers WTCL-C10 (8” Pitless Units), WTCL-C12 (10” Pitless Units), and WTCL-C14 (12” Pitless Units), refer to the link below (details on pages 74 to 77).