What is the function of pressure switches and pressure gauges in a well water system?

A pressure switch controls the submersible pumps’ operation. It has a built-in diaphragm that moves back and forth reacting to the water system pressure. When pressure decreases, the diaphragm retracts, and the spring-loaded contacts will trip causing the contact to snap to the closed position. This is referred to as the cut-in and starts the pump. As the submersible pump builds the system pressure, the diaphragm is forced forward, forcing the contact mechanism to trip again. The contacts snap to the open position, referred to as the cut-out, and stops the pump. The low-pressure cut-off switch is designed to turn off the pump in the event of a low-pressure condition. This feature is designed to protect submersible pumps from running dry if the water level in the well drops below the intake screen of the pump due to drought conditions.

A pressure switch controls the submersible pumps’ operation. It has a built-in diaphragm that moves back and forth reacting to the water system pressure. When pressure decreases, the diaphragm retracts, and the spring-loaded contacts will trip causing the contact to snap to the closed position. This is referred to as the cut-in and starts the pump. As the submersible pump builds the system pressure, the diaphragm is forced forward, forcing the contact mechanism to trip again. The contacts snap to the open position, referred to as the cut-out, and stops the pump. The low-pressure cut-off switch is designed to turn off the pump in the event of a low-pressure condition. This feature is designed to protect submersible pumps from running dry if the water level in the well drops below the intake screen of the pump due to drought conditions.

Boshart offers specialized pressure switches that can be wired in series in addition to the standard pressure switches to provide protection.

In summary, the function of pressure switches in a well water system is to:

- React to water system pressure changes to start and stop the submersible pump

- Provide low-pressure cut-off to protect the pump

- Provide specialization that allows wiring in series to provide protection from high and low water pressure

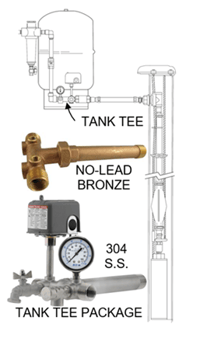

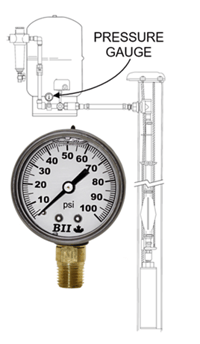

The pressure gauge allows the installer and homeowner to easily monitor what the pressure system is doing and to verify the cut-in and cut-out pressure settings of the pressure switch. Boshart gauges are available in many configurations and quality grades, dry or liquid filled. Most commonly used is a 2” dial steel case gauge with a ¼” lower mount connection. It is installed in one of the two upward facing accessory posts on the tank tee head.

The pressure gauge allows the installer and homeowner to easily monitor what the pressure system is doing and to verify the cut-in and cut-out pressure settings of the pressure switch. Boshart gauges are available in many configurations and quality grades, dry or liquid filled. Most commonly used is a 2” dial steel case gauge with a ¼” lower mount connection. It is installed in one of the two upward facing accessory posts on the tank tee head.

When ordering a pressure gauge the pressure range should be selected to ensure that the gauge will operate in the middle 1/3 of the dial face pressure range. Pressure system gauges are most accurate and will last significantly longer when they operate in the middle of the pressure range.

In summary, the function of a pressure gauge in a well water system is to:

- Easily monitor the system pressure

ADDITIONAL RESOURCES:

https://support.boshart.com/what-is-the-function-of-each-well-water-pressure-system-component

https://support.boshart.com/what-information-is-needed-to-properly-select-a-pressure-switch

https://support.boshart.com/what-is-meant-by-cut-in-and-cut-out-settings

https://support.boshart.com/what-are-the-adjustment-ranges-for-a-ps02-series-pressure-switch

https://support.boshart.com/how-do-i-adjust-a-pressure-switch

https://support.boshart.com/is-the-low-pressure-cut-off-setting-on-a-pressure-switch-adjustable

https://support.boshart.com/is-the-low-pressure-cut-off-setting-on-a-pressure-switch-adjustable

https://support.boshart.com/wiring-a-pressure-switch

https://support.boshart.com/what-is-pressure-switch-differential

https://support.boshart.com/pressure-switch-wont-turn-on

https://support.boshart.com/why-is-my-low-pressure-cut-out-switch-nuisance-tripping

https://support.boshart.com/i-have-totally-messed-up-my-pressure-switch-settings-now-what

https://support.boshart.com/pressure-gauge-range-selection

https://support.boshart.com/what-are-the-advantages-of-installing-a-liquid-filled-gauge

https://support.boshart.com/how-do-i-vent-a-liquid-filled-gauge