What does a pigtail syphon do?

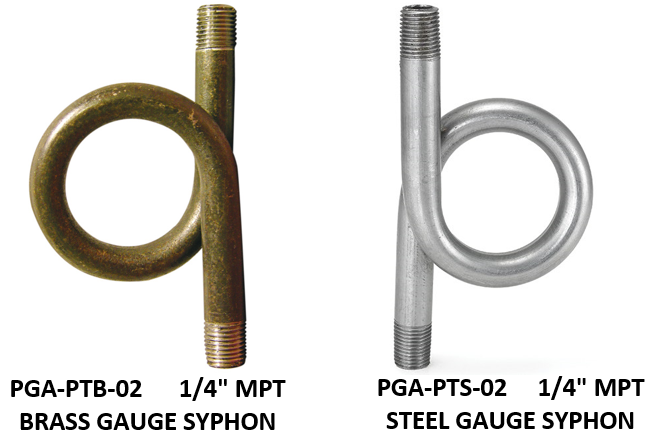

SYPHONS

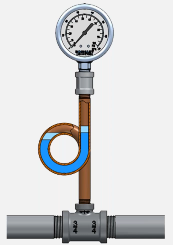

Pressure gauge syphons are intended to protect the pressure gauge from the effect of hot pressure media such as steam and also to reduce the effect of rapid pressure surges.

For protection of:

- Pressure Gauges

- Pressure Switches

- Controllers

- Recording Instruments

Condensate of the pressure medium that is collected inside the coiled portion of the syphon prevents direct contact. When first installed the syphon should be filled with water or any other suitable separating liquid.

Media Temperature Reduction: Approximately 75°F for each 12" section of ½" pipe. The actual reduction is dependent on process and application variables.