Should I install a sump pump check valve?

Yes! Although it is not mandatory by code in all areas, the installation of a sump pump check valve is always a good decision. This article will explain the purpose of a sump pump check valve and the importance of installing one to eliminate sump pump short cycles which lead to premature pump failure and higher electricity bills.

What is a sump pump check valve?

A sump pump check valve is a one way, flapper/swing type valve. A sump pump is installed to pump the water that accumulates in the sump pump basin beneath a basement floor out before the water level rises, overflows, and floods the basement. A sump pump check valve is installed to protect the pump and increase pumping efficiency. This reduces power consumption, prolongs the life of your pump, and protects your basement from getting flooded.

Where are sump pump check valves installed?

They are installed in the discharge pipe from the sump pump. The most suitable location for a sump pump check valve is between 8” up from the pumps discharge to approximately 12” above floor level. Installation above the floor level is convenient for easy inspection, servicing, or replacement of the valve.

The reason for installing the check valve 8” above the pumps discharge is to allow for the drilling of an air release or weep hole to protect against air lock for sump pumps which do not have a built-in air lock prevention system. Always refer to and follow the sump pump manufacturers installation instructions. Installing the sump check valve down in the sump basin can reduce the noise caused by water hammer if a standard gravity closing valve is installed. However, making the required inspections and servicing are not nearly as convenient.

For more information on sump pump weep holes, refer to the link below:

https://support.boshart.com/what-is-a-sump-pump-weep-hole

What are the benefits of installing a sump pump check valve?

Pump Protection - Short cycling causes the pump motor to run hotter. Heat is the enemy of electric motors because it can shorten the life of a pump drastically. By installing a check valve, you will reduce the risk of short cycling which will extend the life of the sump pump.

Short cycling of a sump means that the pump turns on and off too rapidly or too frequently. Short cycling causes the pump motor to run hotter. By installing a check valve, you will reduce the risk of short cycling, especially in smaller size sump basins or in installation with long runs of discharge piping. In large runs of discharge piping, there is a larger volume of water which would drain back into the basin raising the water level, resulting in the pump restarting more frequently than it would otherwise. A check valve will extend the life of the sump pump and save you money.

Pumping Efficiency - When the float switch signals the sump pump to start, the pump forces the water through the valve and out the discharge pipe. When the water level drops, the float switch signals the pump to stop pumping and the water flow stops. Gravity causes the water that is in the discharge pipe to drain back into the pit. The check valve is there to prevent this from happening. The check valve prevents the pump from having to repump the same volume of water over again in the next pump cycle. Eliminating the repumping of this water will save on electricity costs.

What types of sump pump check valves are there?

There are two basic types of swing sump pump check valves. The first is “Gravity Closing” and the second is “Spring Assist Closing” also referred to as “Quiet” or “Silent” check valves.

Sump pump check valves are available in three basic types shown in the photos below. Each type is available in a variety of sizes and connection types. The article below will assist you in the selection process to determine which valve is best suited for your application.

https://support.boshart.com/how-do-i-select-a-check-valve-for-my-sump-pump-application

BSC Series – Black ABS Gravity Closing Type (Economy)

Black ABS Sump Pump Gravity Closing Check Valve Connection Options

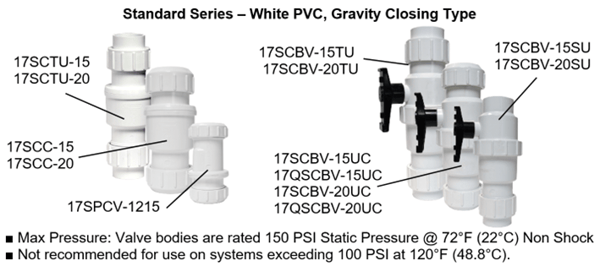

Standard Series – White PVC Gravity Closing Type

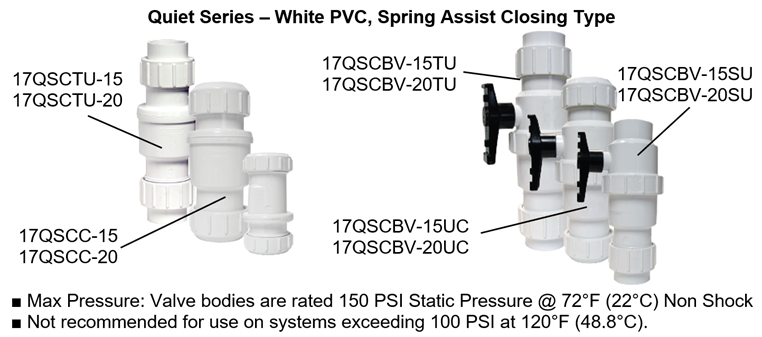

Quiet Series – White PVC Spring Assist Closing Type

How do the different types of check valves work?

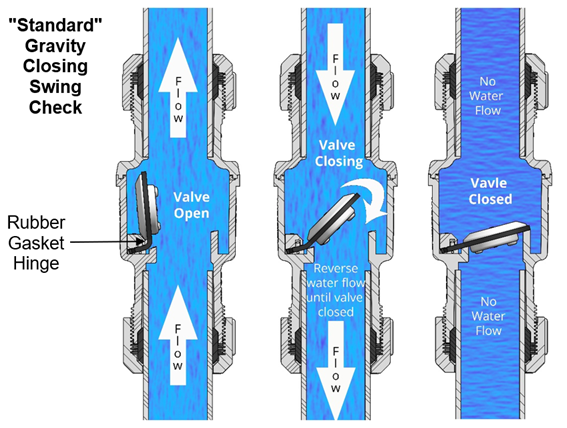

Regardless of the type, they all have the same operating principle at the most basic level. The flapper opens by the force of the water when the pump starts and closes when the pump stops. Below we will explain the difference between valves that close by the force of gravity of the water vs. spring assist closing valves.

GRAVITY CLOSING (Flat Seat)

Some valves on the market are manufactured with a flat seat. Flat seat valves tend to make a loud clunking noise when they close. This is caused by water hammer. The flapper has the greatest distance to travel to the fully closed position resulting in the water gaining momentum before the flapper fully closes. The impact of the flapper hitting the valve seat causes water hammer.

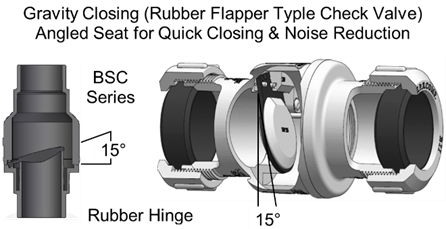

GRAVITY CLOSING (Angled Seat)

Angled seat swing valves are superior and will reduce the water hammer noise to some degree. The angled seat reduces the distance the flapper must travel to the fully closed position resulting in the water gaining less momentum before the flapper fully closes. Therefore, the impact of the flapper hitting the valve seat is reduced and the effects of water hammer are not as noticeable.

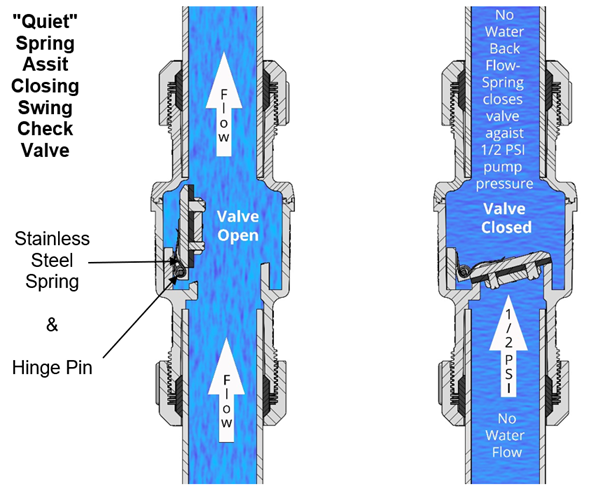

SPRING ASSIST CLOSING (a.k.a. QUIET or SILENT)

As mentioned above these valves are also referred to as “Quiet” or “Silent” check valves and eliminate the clunking noise! This is a result of the spring which applies a low force on the flapper as the water flows through the valve. As the water flow slows when the pump shuts off, the spring softly closes the valve against the seat just before the water stops. Since there is no flow reversal the flapper does not impact with the valve seat and the effects of water hammer are eliminated.

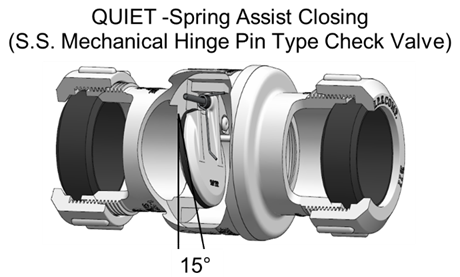

Spring assist valves may have flat or angled seats (illustrated below), both would be quiet in operation. A quiet valve with an angled seat is the superior design.

Conclusion

Not having a sump pump check valve installed results in all the water in the discharge pipe to empty back into the sump pump pit. This makes the water level in the sump pit rise unnecessarily causing the pump to run more often, increasing your energy costs.

Additional Resources

https://support.boshart.com/how-do-i-select-a-check-valve-for-my-sump-pump-application

https://support.boshart.com/what-can-i-do-to-reduce-the-risk-of-problems-with-my-sump-pump-system

https://support.boshart.com/setting-the-tether-point-and-tether-length-on-a-sump-pump-float-switch