Light vs. Heavy Pattern – 304 SS vs. 316 SS - Class 150 Stainless Steel Threaded Fittings

Light vs. Heavy Pattern – 304 SS vs. 316 SS - Class 150 Stainless Steel Threaded Fittings

Light vs. Heavy Pattern – 304 SS vs. 316 SS - Class 150 Stainless Steel Threaded Fittings

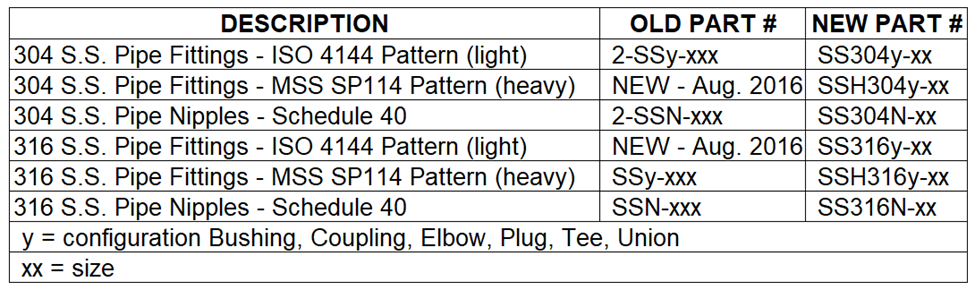

Back in 2016 Boshart added two additional series to our Stainless-Steel Fitting product line as detailed below. We also updated part numbers on our Stainless-Steel Fittings and Nipples at that time.

See the catalogue below for more part number details:

#316 stainless has more nickel and less chromium than #304, as well as 2-3% molybdenum added making it more corrosion resistant, especially in saline or chloride environments. Depending on the application, #304 may also be suitable for food processing, however #316 is superior for corrosion resistance with certain foods.

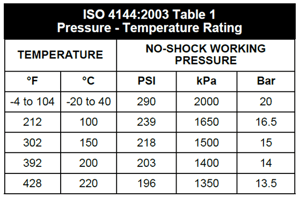

ISO 4144 - LIGHT PATTERN - 304 & 316 STAINLESS STEEL FITTINGS

The ISO 4144 Fittings are an excellent choice for a wide range of applications including residential or commercial water systems. Although the ISO 4144 fittings are much thinner in wall section, they provide high strength and corrosion resistance due to the properties of 304 & 316.

The ISO 4144 Fittings are an excellent choice for a wide range of applications including residential or commercial water systems. Although the ISO 4144 fittings are much thinner in wall section, they provide high strength and corrosion resistance due to the properties of 304 & 316.

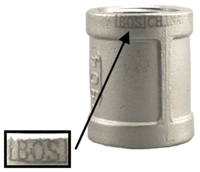

![]() BOS Marking Indicates ISO pattern

BOS Marking Indicates ISO pattern

STANDARD SPECIFICATIONS

STANDARD SPECIFICATIONS

MATERIALS: ASTM A351

DIMENSIONS: ISO 4144 - Pipework - Stainless

Steel Fittings Threaded in accordance with ISO 7-1

THREADS: ANSI B1.20.1

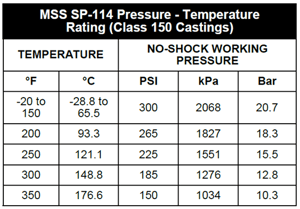

MSS SP-114 - HEAVY PATTERN - 304 & 316 STAINLESS STEEL FITTINGS

The MSS SP-114 Fittings are an excellent choice and are designed for commercial and industrial piping systems in chemical plants, pulp & paper, petroleum, food & beverage, sanitary, steam systems, and general industrial processes that are subject to various stressors

The MSS SP-114 Fittings are an excellent choice and are designed for commercial and industrial piping systems in chemical plants, pulp & paper, petroleum, food & beverage, sanitary, steam systems, and general industrial processes that are subject to various stressors

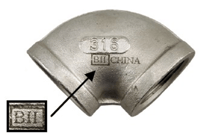

![]() BII Marking indicates MSS pattern

BII Marking indicates MSS pattern

STANDARD SPECIFICATIONS

STANDARD SPECIFICATIONS

MATERIALS: ASTM A351

DIMENSIONS: MSS SP-114 – Corrosion Resistant Fittings Threaded Class 150

THREADS: ANSI B1.20.1

BII Marking indicates MSS pattern

Additional Resources:

https://images.boshart.com/boshartimages/2022/04/SS304N-SS316N-1717-BII.pdf

https://images.boshart.com/boshartimages/2022/04/SS304316RCP-1202RC-BII.pdf

https://support.boshart.com/making-a-leak-proof-stainless-steel-threaded-connection