How does a yard hydrant work?

How does a yard hydrant work?

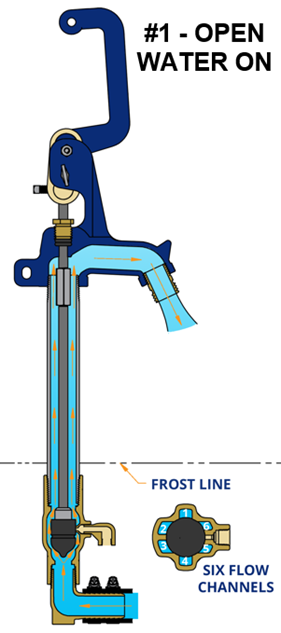

1. OPENING - Raise Handle

1. OPENING - Raise Handle

Lifting the handle raises the connecting rod and plunger off of the valve seat. The raised plunger allows water to flow through the valve body and up the stand pipe. In addition, raising the plunger closes off the drain port. This allows water to flow through the valve port, past the plunger. The water then flows through flow channels up the stand pipe, and finally out the discharge spout.

2. CLOSING & DRAINING - Lower Handle

Closing the handle lowers the connecting rod and plunger down onto the valve body seat. The lowered plunger stops water from the service line and opens the drain port. This allows the water in the stand pipe to drain back down and out of the drain port into the crushed stone drain bed.

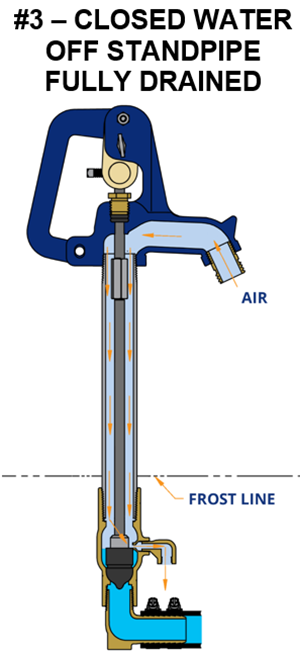

For proper draining to occur, air must be able enter in through the spout. Attaching a hose or some other device to the spout can prevent air from getting in and therefore stopping the draining process.

For proper draining to occur, air must be able enter in through the spout. Attaching a hose or some other device to the spout can prevent air from getting in and therefore stopping the draining process.

3. CLOSED & DRAINED - Handle Down

It takes approximately 45-60 seconds to fully drain a yard hydrant buried 4 ft. The drain port in the valve body is below the frost line so all water above that is drained out and the risk of freezing is eliminated.

Additional Resources:

For additional information on yard hydrants, installation, operating conditions, troubleshooting, and repair, refer to the articles linked below.

https://support.boshart.com/how-do-i-install-my-yard-hydrant

https://support.boshart.com/premium-yhp-vs.-standard-yhs-series-comparison

https://support.boshart.com/what-is-the-maximum-operating-temperature-for-boshart-yard-hydrants

https://support.boshart.com/yard-hydrant-troubleshooting-maintenance

https://support.boshart.com/how-to-adjust-or-repair-boshart-yard-hydrant