How does a BOSHART yard hydrant prevent freezing in below freezing temperatures?

There are three phases of yard hydrant operation which are explained in detail in this article:

There are three phases of yard hydrant operation which are explained in detail in this article:

- OPEN “Water On”

- CLOSED “Water Draining”

- CLOSED “Water Fully Drained”

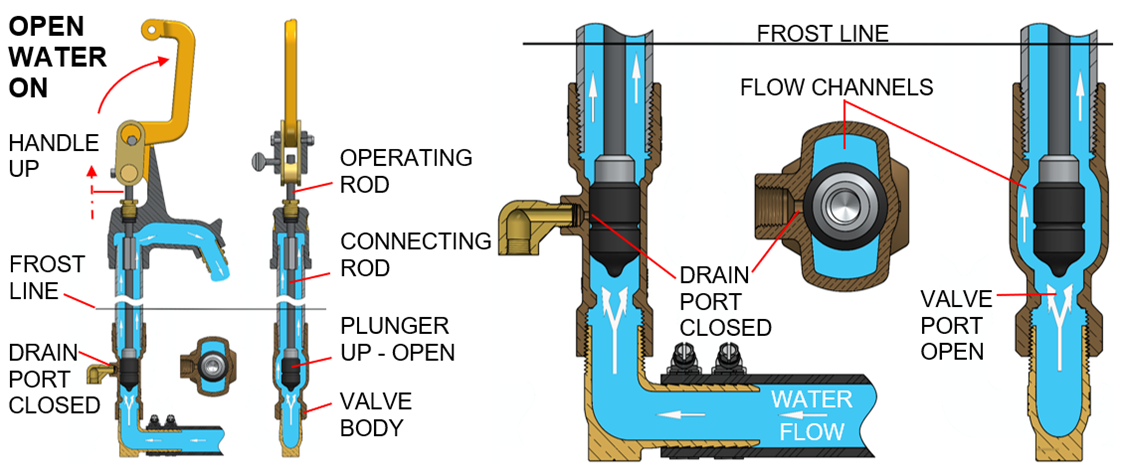

#1 - OPEN WATER ON

When the hydrant handle is raised, the connecting rod lifts the plunger off the valve seat in the valve body.

The raised plunger seals off (closes) the drain port and opens the valve port. This allows water to flow up through the port, around the plunger through two flow channels, continuing up the standpipe, and out the discharge spout.

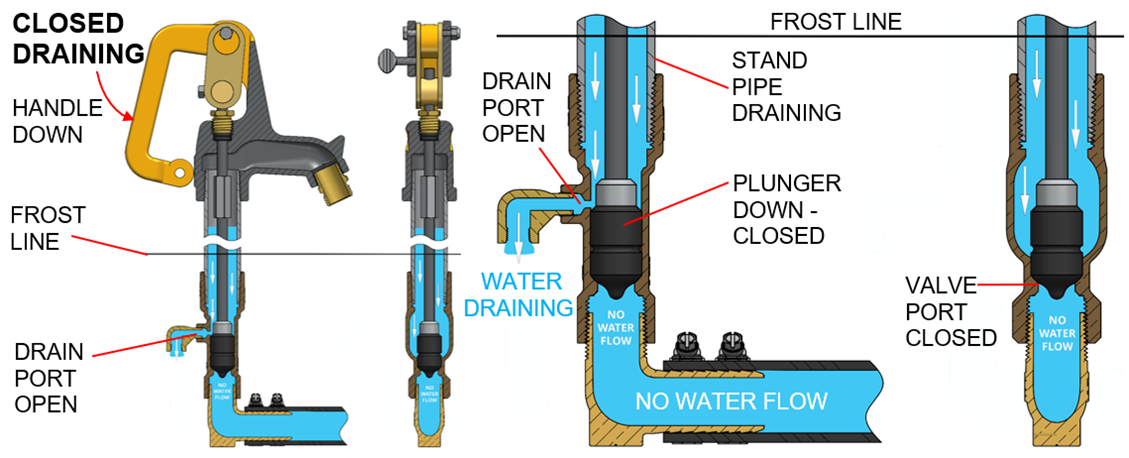

#2 – CLOSED WATER OFF & DRAINING

When the hydrant handle is closed, the connecting rod lowers the plunger against the valve seat. This stops the water flow from the supply line below the frost line where freezing does not occur.

When the plunger is lowered against the valve seat, it opens the drain port and allows the water in the standpipe to drain back down and out of the drain port into the crushed stone drain bed.

IMPORTANT: For proper draining to occur, air must be able enter in through the spout. Attaching a hose or some other device to the spout will prevent air from getting in and therefore stopping the draining process. For this reason, a hose should never be left attached when freezing temperatures could occur.

The time it takes to fully drain the standpipe is approximately 45 to 60 seconds for a 4 foot bury hydrant. Depending on the bury depth and the quality of the drain bed prepared, the drain time could take more or less time.

#3 – CLOSED WATER OFF STANDPIPE FULLY DRAINED

When the standpipe is fully drained all the water above the drain port opening is discharged into the crushed stone drain bed. No water remains above frost line, therefore there is no risk of freezing.

ADDITIONAL RESOURCES

For more information on yard hydrants visit our Knowledge Base center on the Boshart Industries website: www.boshart.com, or at https://support.boshart.com/