Are PG series pressure gauges rated for a maximum overpressure situation?

The PG series gauges are not intended to be exposed to normal operating pressures over 75% of their full scale value. The full scale value is the pressure range that the gauge can measure (the lowest to highest pressure). If the pressure in your system tends to fluctuate, the gauge should be limited to 2/3 of the full scale value. Staying below the maximum range allows for accommodation if pressure spikes or overpressures occur.

The PG series gauges are not intended to be exposed to normal operating pressures over 75% of their full scale value. The full scale value is the pressure range that the gauge can measure (the lowest to highest pressure). If the pressure in your system tends to fluctuate, the gauge should be limited to 2/3 of the full scale value. Staying below the maximum range allows for accommodation if pressure spikes or overpressures occur.

A pressure spike occurs when the pressure sharply increases, and just as suddenly drops back down. In comparison, overpressure is when the pressure regularly sits near or at the maximum range of the gauge.

If the pressure in your system momentarily spikes above 130% of the full scale value, or if your system commonly exhibits overpressure, the gauge may no longer read pressure accurately and is essentially rendered useless.

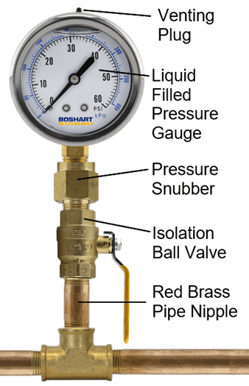

Measures should be taken to protect the gauge from pressure spikes or pressure surges due to water hammer. A pressure snubber between the pressure vessel or piping and the pressure gauge may eliminate the adverse effects that rapid pressure surges, or overpressures, will have on your gauge.

Although pressure spikes or overpressures are not likely to rupture the gauges bourdon tube, it will adversely affect the accuracy and eventually destroy the gauge.

Although pressure spikes or overpressures are not likely to rupture the gauges bourdon tube, it will adversely affect the accuracy and eventually destroy the gauge.

Boshart offers three options of pressure snubbers depending on the fluid media (Snubber - Boshart Industries).

|

Part No. |

Service Application |

|

2-PGA-BS-D |

Heavy Oils |

|

2-PGA-BS-E |

Gasoline, Water or Light Oil |

|

2-PGA-BS-G |

Air and Other Gases |

In addition to a pressure snubber, an isolation valve can be fitted with the pressure gauge to protect it from frequent pressure surges or to allow for easy maintenance. For more information, visit the link below:

Additional Resources

https://support.boshart.com/what-are-the-applications-for-a-pressure-snubber

https://support.boshart.com/should-i-install-an-isolation-valve-with-my-pressure-gauge