Are check valves suitable for back flow prevention?

Are check valves suitable for back flow prevention?

NO! – While check valves are “one-way” valves which do prevent the flow of water in the reverse direction they are not considered approved or certified for back flow prevention and would not be deemed suitable for protecting a potable water system from contamination.

Valves for back flow prevention are called dual check valves and they must meet the required certification standard such as ASSE 1024 and applicable plumbing codes for your area. We offer the GLEN-FLO Model GF8080E / GF8080S6 dual check valve / backflow preventers by Flomatic.

APPLICATION:

Back flow prevention is required in many plumbing codes. It is commonly used to protect potable water systems whether it be municipal or private from contamination due to back siphonage or back pressure which could result in contaminated water polluting the water supply.

Common uses are to protect a home’s private water well system and to protect from back siphonage from barns or yard hydrants. They can also be installed right after the water meter in a municipal water system to protect the towns water supply from any risk of contamination from the homes plumbing system.

ASSE 1024 dual check valves (DuCs) are typically specified for residential projects. They are installed after the water meter. They are rated for back siphonage and backpressure, as well as continuous pressure, but cannot be used when there is an application that requires defense against health hazards.

ASSE 1024 dual check valves (DuCs) are typically specified for residential projects. They are installed after the water meter. They are rated for back siphonage and backpressure, as well as continuous pressure, but cannot be used when there is an application that requires defense against health hazards.

COMPLIES WITH THE FOLLOWING STANDARDS:

- ASSE® 1024

- NSF / ANSI Standard 61 Listed

- CSA®

MATERIALS:

Main valve body: Brass C28500

Elastomers: Buna Nitrile (FDA approved)

Polymer: Delrin®, NSF Listed

Springs: Stainless Steel, 300 Series

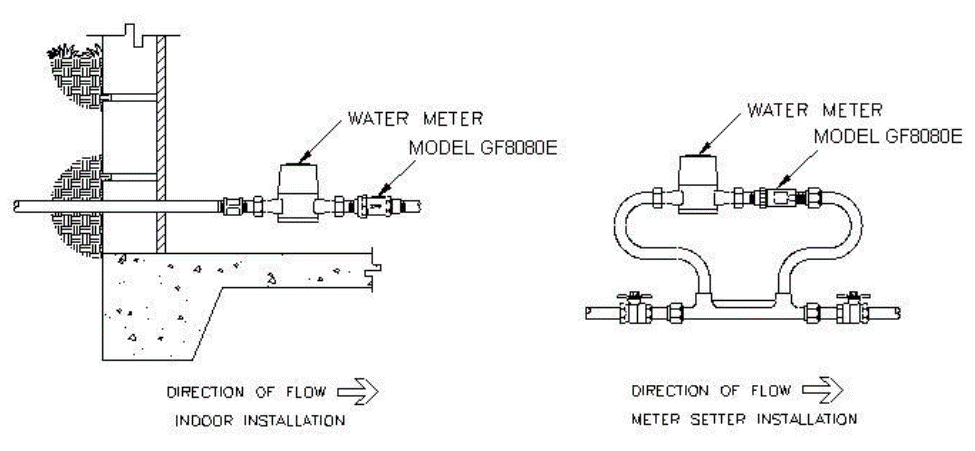

TYPICAL INSTALLATION: FAILURE TO FOLLOW THESE INSTRUCTIONS WILL VOID ANY WARRANTY

Local codes shall govern installation requirements. Unless otherwise specified, the installation shall be in accordance with the manufacturer’s instructions and no part of the unit can be submerged. It is the installers responsibility to make sure that the product and installation meet the requirements of all latest editions of both national and local plumbing and building codes.

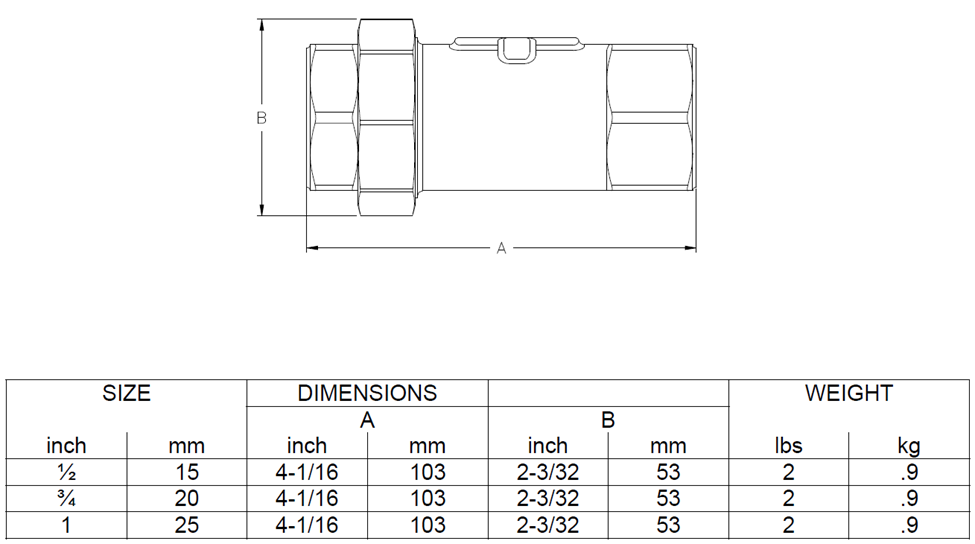

SPECIFICATIONS

SPECIFICATIONS

The dual check valve shall be ASSE® 1024 listed. The main body shall be forged brass (ASTM B 124) and the check assemblies shall be DELRIN®. The seal ring and O-rings shall be Buna Nitrile. The dual check valve shall be a Glen-Flo™ Model GF8080E.

- Max working pressure: 150 PSI

- Max temperature: 180 ºF

- Connection: Threaded ANSI B1.20.1

Additional Resources

https://www.wcsawwa.net/index.php/cross-connection-control/faqs

https://www.awwa.org/portals/0/files/publications/documents/m14lookinside.pdf